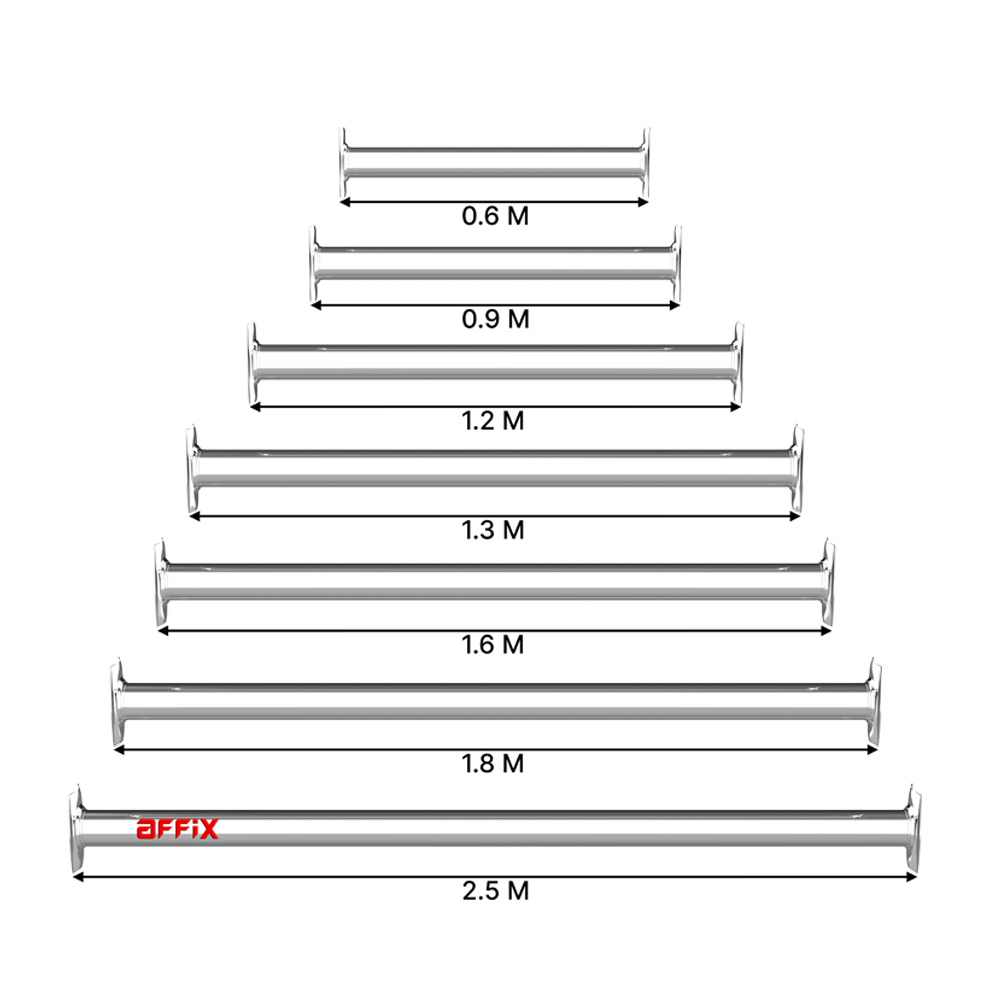

Cuplock Ledger

Model No. FCC02

- Ledgers are used as the main horizontal connecting members for the Cuplock system.

- Ledgers are manufactured from 48.3mm OD x 3.2mm thick scaffolding tube with forged steel blades at both the ends.

- The ledger blades fit into the bottom cups of the standards and are locked in place by the corresponding top cups.

- These are available in various lengths to provide the desired grid specification for scaffolding or formwork

Specifications

Cuplock Ledger

|

Video

Currently Unavailable

Thank you for reading this post, don't forget to subscribe!3D Display

Currently Unavailable

Thank you for reading this post, don't forget to subscribe!