Mobile Scaffolding for Sale in Finland

Mobile scaffolding has become an essential solution for construction and maintenance projects across Finland, providing flexibility, safety, and efficiency for professionals and enthusiasts alike. Designed for mobility and ease of assembly, mobile scaffolds offer a practical alternative to traditional fixed scaffolding systems, enabling quick access to elevated work areas without compromising stability. From building renovations to industrial maintenance, these scaffolds streamline operations, reduce labor requirements, and enhance workplace safety. With various configurations available, including mobile scaffold platforms and mobile tower scaffolds, Finnish businesses and contractors increasingly rely on these solutions to meet project demands while optimizing both time and resources.

What is Mobile Scaffolding?

Mobile scaffolding is a versatile and flexible structure designed to provide safe elevated work surfaces that can be easily moved across different work areas. Unlike traditional scaffolding, which is fixed and requires disassembly to relocate, mobile scaffolds are equipped with wheels or castors, allowing smooth mobility while maintaining stability. This adaptability makes mobile scaffolding an essential tool for construction, maintenance, and industrial operations in Finland, where varying project sizes and diverse building types demand reliable and efficient access solutions.

At its core, mobile scaffolding consists of a sturdy frame, platform boards, guardrails, and adjustable components that enable height customization. The design ensures that workers can reach elevated areas without compromising safety or operational efficiency. Mobile scaffolds are commonly used for indoor and outdoor tasks, including renovations, painting, electrical work, and inspection projects.

Types of Mobile Scaffolding

-

Mobile Scaffold Platforms: Mobile scaffold platforms provide a wide working surface for multiple personnel and equipment. They are ideal for projects requiring extended horizontal reach and can be adjusted in height for various applications. Their design often includes safety features like guardrails and stabilizers, making them suitable for both commercial and industrial use.

-

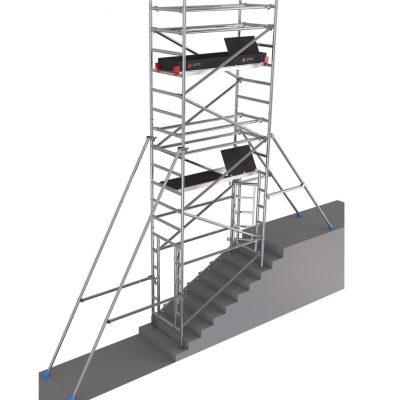

Mobile Tower Scaffolds: Mobile tower scaffolds are tall, narrow structures designed to provide access to elevated work zones in areas with limited floor space. Equipped with locking castors for stability, they are often used in construction sites, warehouses, and facilities where vertical reach is essential. The modular nature allows for easy assembly and disassembly while maintaining structural integrity.

-

Specialized Mobile Scaffolds: Certain projects require customized mobile scaffolding configurations, such as adjustable-height scaffolds for uneven surfaces or compact units for confined areas. These scaffolds combine mobility with adaptability, catering to specialized tasks while ensuring safety compliance and ergonomic accessibility.

Applications of Mobile Scaffolding

Mobile scaffolding is widely applied across various industries in Finland due to its flexibility and safety advantages:

-

Construction and Renovation: Mobile scaffolds allow easy access to façades, ceilings, and walls for installation, repairs, or maintenance. Their adjustable heights ensure workers can perform tasks at multiple levels without repeated disassembly.

-

Industrial Maintenance: Factories, warehouses, and production facilities benefit from mobile scaffolds when servicing machinery, pipelines, or lighting systems. Their mobility enables efficient transitions between work zones.

-

Painting and Decorating: Painters and decorators utilize mobile scaffolds for smooth movement across walls and ceilings. The stable platforms reduce the need for ladders, enhancing safety and productivity.

-

Electrical and Mechanical Work: Mobile scaffolds facilitate access to wiring, HVAC systems, and plumbing installations. Their design supports tools and equipment, making complex tasks more manageable.

-

Events and Setup: Temporary structures for lighting, staging, or audiovisual equipment installation often rely on mobile scaffolds for quick, safe, and elevated access.

Components of Mobile Scaffolding

Understanding the components of mobile scaffolds is essential for selecting the right solution for specific tasks:

-

Frames: The main structure providing support and stability. Frames are typically constructed from steel or aluminum, offering durability and lightweight handling.

-

Platforms: Horizontal working surfaces where personnel stand or place tools. Platforms are adjustable in height and often equipped with non-slip materials for safety.

-

Guardrails: Essential for preventing falls, guardrails surround platforms to provide a secure working environment.

-

Castors/Wheels: High-quality wheels with locking mechanisms allow mobility while ensuring stability during work. Some models include swivel or adjustable castors for uneven surfaces.

-

Braces and Stabilizers: These components reinforce structural integrity, ensuring the scaffold remains stable during use.

Advantages of Modular Design

Mobile scaffolding is often modular, allowing components to be added, removed, or reconfigured depending on project requirements. This flexibility enables:

-

Customizable platform sizes for varying work areas.

-

Adjustable heights for multi-level tasks.

-

Easy transport and storage, reducing logistical challenges.

-

Compatibility with safety accessories, such as toe boards and ladders.

Safety Considerations

Mobile scaffolding in Finland adheres to strict safety regulations, ensuring that users are protected during operation. Proper inspection, assembly, and maintenance are critical, particularly when moving the scaffold across uneven surfaces or working at significant heights. High-quality mobile scaffolds include locking mechanisms, guardrails, and stabilizers to meet these safety standards.

Why is Mobile Scaffolding Popular?

Mobile scaffolding has become a standard solution for construction, industrial, and maintenance projects in Finland, and its popularity continues to grow due to the combination of practicality, safety, and adaptability it offers. Professionals across industries increasingly prefer mobile scaffolds because they provide a reliable, efficient, and versatile alternative to fixed scaffolding systems, significantly improving workflow and productivity.

Practicality and Convenience

One of the primary reasons mobile scaffolding has gained popularity is its unmatched practicality. These scaffolds are designed for ease of movement, allowing workers to relocate the structure quickly without disassembly. This feature saves time and reduces labor costs on projects that involve frequent repositioning or multiple work zones. The mobility factor also ensures that workers can handle large or complex spaces efficiently.

Additionally, mobile scaffolds are available in various configurations, including mobile scaffold platforms and mobile tower scaffolds, making them suitable for both horizontal and vertical access needs. Their modular design allows users to adjust platform height, expand the working area, or customize the scaffold according to project demands. This adaptability has made them a preferred choice for both large construction sites and smaller maintenance operations.

Safety and Stability

Safety remains a central consideration in Finland’s construction and industrial sectors, and mobile scaffolding addresses this need effectively. High-quality mobile scaffolds are equipped with locking castors, guardrails, stabilizers, and robust frames that provide stability while allowing mobility. The inclusion of non-slip platforms and secure ladder access further reduces the risk of accidents during elevated work.

For contractors and facility managers, this combination of safety and mobility is particularly valuable. It ensures compliance with local safety regulations while maintaining operational efficiency, which contributes significantly to the popularity of mobile scaffolding.

Efficiency and Productivity

Time efficiency is another reason mobile scaffolds are widely adopted. Workers can cover large areas without constantly dismantling and rebuilding scaffolding, minimizing downtime between tasks. The ease of assembly and disassembly further enhances productivity, especially in projects with tight schedules.

The ability to transport the scaffold across different floors or work areas without interruption enables teams to maintain workflow continuity. This feature is particularly useful in industrial facilities, commercial buildings, and renovation projects, where repeated repositioning is often necessary.

Cost-Effectiveness

Mobile scaffolding is often more cost-effective than traditional fixed scaffolds. The reusable components, minimal assembly time, and reduced labor requirements result in lower overall project expenses. Companies in Finland increasingly recognize that investing in mobile scaffolds can provide long-term savings, especially for contractors managing multiple projects or recurring maintenance work.

Versatility Across Industries

The versatility of mobile scaffolding contributes to its widespread adoption. Key applications include:

-

Construction Projects: Providing access to façades, ceilings, and walls for installation, repairs, or finishing work.

-

Industrial Maintenance: Facilitating safe inspections and maintenance in factories, warehouses, and production plants.

-

Painting and Decorating: Offering smooth, adjustable platforms that improve coverage and efficiency.

-

Electrical and Mechanical Work: Allowing technicians to reach elevated equipment, lighting systems, and HVAC installations safely.

-

Event Setup and Management: Enabling safe installation of lighting, staging, and audiovisual equipment in public venues or corporate settings.

The adaptability of mobile scaffolds to various environments—indoor, outdoor, uneven surfaces, and confined spaces—further reinforces their popularity.

Advantages Over Traditional Scaffolding

Mobile scaffolding surpasses fixed scaffolds in several practical aspects:

-

Quick Mobility: Unlike permanent scaffolds, mobile scaffolds can be easily moved to different locations without full disassembly.

-

Reduced Setup Time: Modular design allows for fast assembly and disassembly.

-

Enhanced Safety Features: Integrated guardrails, stabilizers, and locking wheels provide a secure working environment.

-

Cost Savings: Lower labor and material requirements reduce project expenses.

-

Multi-Purpose Use: Suitable for construction, maintenance, industrial, and event applications.

Growing Demand in Finland

The Finnish construction and industrial sectors have increasingly adopted mobile scaffolding due to a combination of labor efficiency, safety, and regulatory compliance. Contractors, maintenance teams, and facility managers prefer mobile scaffolds because they streamline operations while reducing risk. Additionally, technological advancements in scaffold design have improved stability, portability, and ease of use, further boosting demand.

Moreover, with the emphasis on workplace safety and operational efficiency in Finland, mobile scaffolding aligns perfectly with industry priorities. Businesses can complete tasks faster while adhering to safety regulations, which has significantly contributed to the sustained popularity of mobile scaffolds across the country.

Benefits of Mobile Scaffolding

Mobile scaffolding has become an essential choice for construction and industrial projects in Finland due to its numerous advantages. Designed to offer both safety and convenience, mobile scaffolds combine flexibility, stability, and efficiency, making them a practical solution for professionals who require reliable elevated access. Whether in construction, maintenance, painting, or industrial applications, mobile scaffolding enhances workflow, reduces risks, and provides significant operational benefits.

-

Enhanced Mobility: One of the most significant benefits of mobile scaffolding is its mobility. Equipped with high-quality wheels and locking castors, these scaffolds can be moved across work areas effortlessly. This eliminates the need for repeated assembly and disassembly, saving valuable time and labor costs while improving project efficiency.

-

Time Efficiency: Mobile scaffolding allows workers to quickly adjust positions and heights, completing tasks faster than with fixed scaffolds or ladders. The easy setup and dismantling process further streamline operations, allowing teams to focus on work rather than scaffold management.

-

Safety Compliance: Safety is a priority in any elevated work environment, and mobile scaffolds are designed to meet rigorous standards. Features such as guardrails, stabilizers, non-slip platforms, and secure ladders minimize the risk of falls and accidents. This ensures compliance with local regulations in Finland and enhances worker confidence.

-

Versatility: Mobile scaffolds can be adapted to a wide range of applications, from construction and renovation to industrial maintenance and event setups. Their modular design allows adjustments in height, platform size, and configuration, making them suitable for both small-scale and large-scale projects.

-

Cost Savings: Investing in mobile scaffolding can reduce project expenses over time. With reusable components, minimal assembly requirements, and reduced labor needs, companies save on both equipment and operational costs. The long-term durability of high-quality scaffolds also contributes to cost-effectiveness.

-

Accessibility in Confined Spaces: Mobile scaffolds are designed to provide access in areas where traditional scaffolding may not fit. Mobile tower scaffolds, in particular, can navigate narrow spaces while offering stable elevated platforms, making them ideal for indoor projects and restricted work zones.

-

Stability and Structural Integrity: Despite their mobility, these scaffolds are engineered for stability. Locking mechanisms, braces, and reinforced frames ensure the structure remains secure during use. This combination of mobility and strength makes mobile scaffolding a reliable solution for various tasks.

-

Reduced Labor Requirements: Traditional scaffolding often demands significant manpower for assembly and relocation. Mobile scaffolds simplify this process, requiring fewer workers to set up or move the structure. This efficiency not only reduces labor costs but also lowers the potential for human error during assembly.

-

Support for Equipment and Materials: Mobile scaffolds provide a stable platform for both personnel and tools. Platforms can hold equipment and materials securely, allowing workers to complete tasks without repeatedly fetching supplies. This enhances workflow and reduces interruptions, improving overall productivity.

-

Adaptability for Multiple Projects: Companies with multiple projects or maintenance tasks benefit from mobile scaffolds because the same equipment can be used across different sites. Their portability and modular design make them a practical investment for businesses that require flexibility and consistent performance.

-

Improved Ergonomics: Mobile scaffolding allows workers to maintain proper posture and positioning while performing elevated tasks. Adjustable platform heights and easy access ladders reduce strain and fatigue, contributing to a safer and more comfortable working environment.

-

Ease of Storage and Transportation: When not in use, mobile scaffolds can be disassembled and stored compactly. Their lightweight components facilitate transport between sites, making logistics simpler for contractors and facility managers. This portability is particularly useful for seasonal or temporary projects.

-

Multi-Level Functionality: Many mobile scaffold systems can be configured for multiple levels, providing elevated platforms for different heights simultaneously. This feature supports large-scale projects that require simultaneous access to various work zones, optimizing time and labor efficiency.

-

Environmentally Practical: Mobile scaffolds are often made from durable materials like aluminum or steel, which are reusable and recyclable. Their long lifespan and adaptability reduce the need for repeated purchases, supporting sustainable construction and maintenance practices.

Features of Mobile Scaffolding

Mobile scaffolding has become an indispensable tool in construction, maintenance, and industrial projects in Finland due to its thoughtful design and array of features. These scaffolds are engineered to provide safety, flexibility, and efficiency, making them a preferred solution for professionals who need reliable elevated access. Understanding the features of mobile scaffolding helps businesses select the right equipment for specific projects while maximizing productivity and safety.

-

High-Quality Frames: The frame is the backbone of mobile scaffolding. Typically constructed from aluminum or steel, these frames provide a balance between strength and lightweight portability. Aluminum frames are favored for their corrosion resistance and ease of handling, while steel frames offer additional durability for heavy-duty applications. Strong frames ensure the scaffold maintains structural integrity even under high load conditions.

-

Adjustable Platforms: Mobile scaffolding platforms can be adjusted to various heights, allowing workers to reach different elevated zones without relocating the entire structure. This flexibility is essential for projects that require multi-level access. Platforms are usually made of reinforced materials and often include non-slip surfaces to enhance worker safety.

-

Locking Castors and Wheels: Mobility is one of the defining features of mobile scaffolding, and high-quality castors enable smooth movement across work areas. Locking mechanisms on the wheels ensure stability during use, preventing unwanted movement. Swivel castors are often included to allow maneuvering in tight spaces or confined work zones.

-

Guardrails and Safety Barriers: Safety is a primary concern in elevated work. Mobile scaffolds include guardrails and toe boards that prevent accidental falls and protect workers. Guardrails are typically installed on all open sides of the platform and meet Finnish safety standards, providing a secure working environment.

-

Braces and Stabilizers: To maintain stability, mobile scaffolding incorporates braces and stabilizers that reinforce the frame. Diagonal braces prevent lateral movement, while base stabilizers ensure the scaffold remains steady even on uneven surfaces. These features are critical for maintaining balance during work at elevated heights.

-

Modular Design: Many mobile scaffolding systems are modular, allowing users to assemble, disassemble, or reconfigure the scaffold according to project requirements. This design feature enables customization of platform size, scaffold height, and structure layout, making it suitable for a wide range of applications.

-

Multi-Level Capability: Mobile scaffolds can be configured to provide multiple working levels simultaneously. This feature is particularly beneficial for large-scale projects where multiple workers need access at different heights. Multi-level scaffolds also reduce setup time, as the structure can accommodate various tasks without needing separate units.

-

Tool and Equipment Support: Mobile scaffolding platforms are designed to hold both personnel and tools safely. Reinforced platform surfaces provide space for equipment, materials, or small machinery, reducing the need for repeated trips up and down the scaffold. This improves workflow efficiency and minimizes interruptions during work.

-

Compact Storage and Transport: The design of mobile scaffolds allows for easy disassembly and compact storage. Lightweight frames, foldable components, and modular parts ensure that scaffolds can be transported between sites without excessive effort. This feature is particularly advantageous for companies managing multiple projects or working in urban environments with limited space.

-

Durable Materials: Mobile scaffolds are built from high-quality, corrosion-resistant materials to withstand harsh weather conditions and frequent use. Aluminum and galvanized steel components ensure long-lasting performance and reduced maintenance requirements, making them suitable for indoor and outdoor applications.

-

Ease of Assembly: The assembly process of mobile scaffolding is designed to be straightforward, often requiring minimal tools or specialized knowledge. Components are designed to fit together seamlessly, allowing quick setup and reducing downtime on site. This feature ensures that projects can begin promptly without delays caused by complicated assembly procedures.

-

Customizable Accessories: Mobile scaffolding can be enhanced with accessories such as ladders, safety gates, toe boards, and platform extensions. These accessories provide additional safety, functionality, and convenience, allowing scaffolds to adapt to specific project requirements. Customizable components also increase versatility for different work environments.

-

Ergonomic Design: Mobile scaffolds are designed with worker comfort in mind. Proper platform height, stable surfaces, and easy access ladders reduce strain and fatigue during extended use. Ergonomic design contributes to a safer and more productive work environment, minimizing the risk of injuries.

-

Compliance with Safety Standards: Finnish construction and industrial regulations emphasize safety and quality. Mobile scaffolding is designed to comply with these standards, ensuring that all components, load capacities, and safety features meet or exceed legal requirements. Compliance guarantees peace of mind for contractors and facility managers using the scaffolds.

-

Versatile Application: The combination of mobility, modularity, and structural integrity allows mobile scaffolds to be used in diverse projects. They are suitable for construction, industrial maintenance, painting, electrical work, and even event setup. This versatility makes them a practical investment for companies that handle multiple types of projects.

Tips to Follow While Looking for Mobile Scaffolding

Selecting the right mobile scaffolding for your construction or maintenance project in Finland requires careful consideration. With various types available, including mobile scaffold platforms and mobile tower scaffolds, choosing the appropriate scaffold ensures safety, efficiency, and durability. Professionals and enthusiasts must assess multiple factors before making a purchase or rental decision to maximize value and meet project requirements.

1. Assess Your Project Needs

Before selecting mobile scaffolding, it is essential to define the scope of your project:

-

Determine the height requirements for the work area.

-

Evaluate the size of the platform needed for personnel and equipment.

-

Identify the number of workers who will use the scaffold simultaneously.

-

Consider the type of tasks—painting, maintenance, construction, or inspection.

Knowing these parameters helps narrow down options and ensures the scaffold meets both operational and safety needs.

2. Consider the Load Capacity

Mobile scaffolding must safely support the weight of workers, tools, and materials. Check the scaffold’s maximum load capacity to ensure it accommodates your specific needs. Overloading a scaffold can lead to instability or accidents. High-quality mobile scaffolds in Finland are engineered to distribute weight evenly across platforms, providing enhanced stability and structural integrity.

3. Evaluate Mobility Features

Mobility is a defining feature of these scaffolds, so consider the quality of the wheels or castors:

-

Look for locking mechanisms to secure the scaffold during use.

-

Check for swivel or adjustable castors for easier movement on uneven surfaces.

-

Ensure the wheels are durable and smooth-rolling for indoor and outdoor applications.

Proper mobility features enhance productivity by allowing safe repositioning without frequent disassembly.

4. Inspect Safety Features

Safety is paramount when working at height. Evaluate the scaffold’s safety components:

-

Guardrails or safety rails surrounding all platforms

-

Non-slip platform surfaces

-

Toe boards to prevent tools or materials from falling

-

Stabilizers and braces for enhanced stability

-

Compliance with Finnish and international safety standards

Choosing scaffolds with comprehensive safety features reduces risks and ensures regulatory compliance.

5. Consider Material and Durability

The scaffold’s material affects its weight, strength, and longevity:

-

Aluminum scaffolds are lightweight, portable, and resistant to corrosion.

-

Steel scaffolds provide maximum strength and durability, ideal for heavy-duty use.

-

Inspect coatings, welds, and joints for long-term reliability.

Durable materials minimize maintenance needs and allow repeated use across multiple projects.

6. Check for Modular Design

A modular scaffold design offers versatility:

-

Adjustable platforms to suit different heights

-

Expandable configurations for larger working areas

-

Easy assembly and disassembly without specialized tools

-

Ability to add accessories like ladders, tool trays, or safety nets

Modular scaffolds provide flexibility, making them suitable for both indoor and outdoor projects of varying complexity.

7. Consider Indoor and Outdoor Use

Determine whether the scaffold will be used indoors, outdoors, or both. Some scaffolds are specifically designed for uneven terrain, while others are optimized for smooth surfaces. Look for features such as adjustable castors, stabilizers, and weather-resistant materials if the scaffold will be used in outdoor conditions.

8. Assess Storage and Transport Requirements

Mobile scaffolds should be easy to store and transport:

-

Check if the scaffold can be disassembled and stacked for compact storage.

-

Ensure the components are lightweight for safe handling.

-

Consider transport logistics if the scaffold will be moved between multiple sites.

Efficient storage and transport reduce logistical challenges and improve overall project management.

9. Budget Considerations

While it is important to prioritize quality and safety, cost remains a factor:

-

Compare options based on durability, features, and load capacity.

-

Consider long-term investment versus short-term rental costs.

-

Avoid low-quality scaffolds that compromise safety or longevity.

Investing in reliable mobile scaffolding can reduce maintenance costs, minimize downtime, and enhance project efficiency over time.

10. Consult With Experts

Engaging with scaffolding professionals or suppliers can provide valuable guidance:

-

Confirm scaffold suitability for your project’s height, weight, and application.

-

Verify compliance with safety regulations.

-

Discuss options for accessories and modular extensions.

Expert advice ensures that you choose the right scaffold configuration for maximum performance and safety.

Why Choose Affix Scaffolding?

Selecting the right supplier for mobile scaffolding in Finland is crucial for ensuring safety, efficiency, and project success. Affix Scaffolding stands out as a trusted provider, offering high-quality mobile scaffolding solutions designed to meet the diverse needs of construction professionals, maintenance teams, and industrial operators. With a commitment to excellence, Affix Scaffolding provides a range of products, including mobile scaffold platforms and mobile tower scaffolds, ensuring that every project is supported by reliable, durable, and safe access solutions.

Expertise and Industry Knowledge

Affix Scaffolding brings extensive expertise in scaffolding solutions, backed by years of experience in the Finnish market. Their team understands the specific demands of different industries, including construction, industrial maintenance, and facility management. This knowledge allows them to recommend the most suitable mobile scaffolding configurations for each project, optimizing both safety and efficiency.

Comprehensive Product Range

Affix Scaffolding offers a diverse selection of mobile scaffolding options:

-

Mobile Scaffold Platforms: Provide spacious, adjustable working surfaces for multiple personnel and equipment.

-

Mobile Tower Scaffolds: Offer tall, narrow structures for vertical access in confined areas or spaces requiring maximum height.

-

Specialized Mobile Scaffolds: Custom configurations to accommodate unique project requirements.

By offering a comprehensive product range, Affix Scaffolding ensures that clients can find the right solution for their specific work environment, regardless of complexity or scale.

Safety and Compliance

Safety is a core priority for Affix Scaffolding. All mobile scaffolds are manufactured with high-quality materials, including steel and aluminum, to ensure structural integrity. Features such as guardrails, stabilizers, locking castors, and non-slip platforms are standard, providing a secure working environment for personnel.

Additionally, Affix Scaffolding products comply with Finnish and international safety standards, giving clients peace of mind while performing elevated tasks. Regular inspections and adherence to safety regulations further demonstrate the company’s commitment to protecting both workers and assets.

Durability and Reliability

Affix Scaffolding’s mobile scaffolds are designed for long-term use, offering durability and resistance to wear, corrosion, and environmental factors. Whether used indoors or outdoors, their scaffolds maintain performance over time, reducing the need for frequent replacements and ensuring consistent project reliability.

The use of high-quality materials, robust design, and precise manufacturing ensures that every scaffold can withstand the demands of heavy-duty construction and maintenance operations.

Versatility and Adaptability

Affix Scaffolding’s products are built to adapt to a wide range of applications:

-

Adjustable platforms for different heights and work zones

-

Modular components for expansion or reconfiguration

-

Compatibility with safety accessories such as ladders, tool trays, and toe boards

-

Portability for indoor, outdoor, and confined spaces

This versatility allows contractors and facility managers to maximize productivity while maintaining safety across varying work conditions.

Expert Consultation and Support

Affix Scaffolding provides expert guidance to help clients select the most suitable mobile scaffolding solutions. Their team offers:

-

Project-specific recommendations based on height, load, and application requirements

-

Advice on assembly, mobility, and safety practices

-

Support for customizing scaffold configurations to meet unique needs

By combining product excellence with professional consultation, Affix Scaffolding ensures clients make informed decisions that enhance both efficiency and safety.

Efficient Assembly and Logistics

Affix Scaffolding prioritizes ease of use and operational efficiency. Their mobile scaffolds feature simple assembly systems, enabling quick setup and disassembly without specialized tools. The lightweight modular components allow for easy transport and storage, making them practical for projects across multiple sites in Finland.

Efficient logistics reduce downtime, improve workflow, and allow teams to focus on completing tasks rather than managing scaffolding equipment.

Customer-Centric Approach

Affix Scaffolding’s commitment to client satisfaction goes beyond providing high-quality products. They emphasize a customer-centric approach, ensuring that every interaction—from consultation to delivery—meets professional standards. This focus on reliability, responsiveness, and tailored solutions strengthens client trust and supports long-term partnerships.

FAQs

1. What is mobile scaffolding, and how does it differ from traditional scaffolds?

Mobile scaffolding is a portable scaffold system designed for easy movement across work areas. Unlike traditional fixed scaffolds, mobile scaffolds offer adjustable heights, lockable castors, and modular platforms, providing safer and more efficient access for construction, maintenance, or industrial tasks in Finland.

2. What types of mobile scaffolding are available in Finland?

In Finland, mobile scaffolding includes mobile scaffold platforms, mobile tower scaffolds, and specialized modular systems. Each type offers specific benefits, such as wide platforms for multiple workers, tall structures for vertical access, or customizable configurations for confined spaces or unique project requirements.

3. How do I choose the right mobile scaffold for my project?

Selecting the right mobile scaffold depends on factors like platform size, height requirements, load capacity, and work environment. Assessing whether you need a mobile scaffold platform or mobile tower scaffold ensures efficiency, safety, and suitability for indoor, outdoor, or confined spaces in Finnish work settings.

4. Are mobile scaffolds safe to use?

Yes, mobile scaffolds are designed with safety in mind. Features include guardrails, stabilizers, non-slip platforms, and locking castors. High-quality scaffolds, including mobile scaffold platforms and mobile tower scaffolds, comply with Finnish safety standards, minimizing risks for construction, industrial, and maintenance tasks.

5. Can mobile scaffolds be used both indoors and outdoors?

Absolutely. Mobile scaffolds are suitable for indoor and outdoor projects. Adjustable castors and stabilizers allow safe movement on smooth and uneven surfaces, while durable materials like aluminum and steel ensure long-lasting performance, whether in construction sites, industrial facilities, or maintenance work across Finland.

6. How much weight can a mobile scaffold support?

Load capacity varies by scaffold type and model. Mobile scaffold platforms and mobile tower scaffolds are engineered to support multiple workers, tools, and materials safely. Always check manufacturer specifications to ensure the scaffold accommodates project requirements without compromising stability or safety.

7. Is it easy to assemble and disassemble mobile scaffolding?

Yes, mobile scaffolding is designed for quick assembly and disassembly. Modular components fit together securely without specialized tools, saving time and labor. This efficiency allows teams to focus on work while maintaining safe and reliable access to elevated areas across various projects.

8. How does mobility improve project efficiency?

Mobility allows scaffolds to be moved quickly across work areas without full disassembly. Mobile scaffold platforms and mobile tower scaffolds enable workers to reach multiple locations efficiently, reducing downtime, optimizing labor, and streamlining workflows for construction, maintenance, or industrial tasks in Finland.

9. What materials are mobile scaffolds made of?

Mobile scaffolds are commonly made from steel or aluminum. Steel offers maximum strength and durability for heavy-duty projects, while aluminum is lightweight, corrosion-resistant, and portable. Both materials ensure long-term reliability and support safe elevated work environments for professionals and enthusiasts.

10. Why should I choose Affix Scaffolding for mobile scaffolding in Finland?

Affix Scaffolding provides high-quality mobile scaffolds with robust construction, safety features, and modular designs. Their expert guidance, compliance with Finnish safety standards, and range of mobile scaffold platforms and mobile tower scaffolds ensure efficient, reliable, and versatile solutions for professional projects across Finland.