Products

-

Adjustable Base Jack

-

Adjustable U Head Jack

-

Adjustable Universal Jack

-

Aluminium Beam-Double Web Heavy

-

Aluminium Beam-Single Web Heavy

-

Aluminium Beam-Single Web Light

-

Aluminium Lattice beam

-

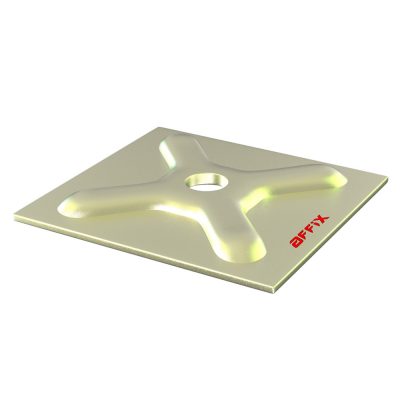

Base Plate

-

Beam Bracket

-

Board Retaining Coupler

-

Cantilever Frame

-

Castor Wheels

-

Cuplock Intermediate Transom

-

Cuplock Ledger

-

Cuplock Spigot Pin

-

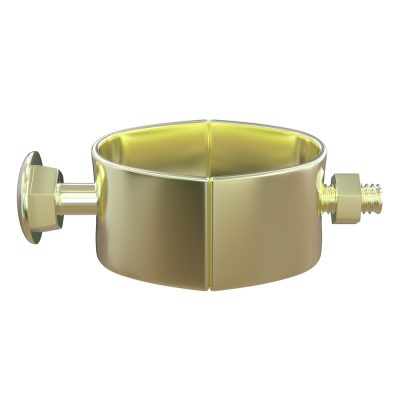

Cuplock Standard

-

Cuplock Swivel Face Braces

-

Double Cantilever Frame

-

Double Coupler

-

Fork U-Head Jack

-

Galvanized Pipe

-

Girder Coupler

-

H Frames

-

H20 Beams

-

Ladder Beam

-

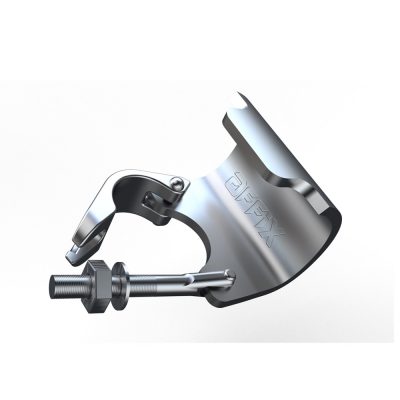

Ladder Clamp

-

Pressed Sleeve Coupler

-

Prop Jacks

-

Push Pull Prop

-

Single Coupler

-

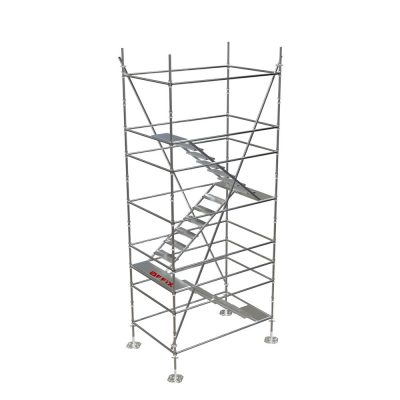

Staircase Unit

-

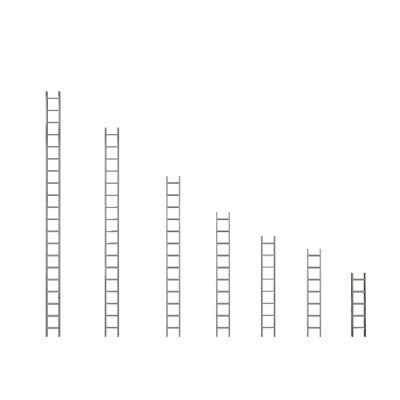

Steel Ladder

-

Steel Planks

-

Swivel Adjustable Base Jack

-

Swivel Coupler

-

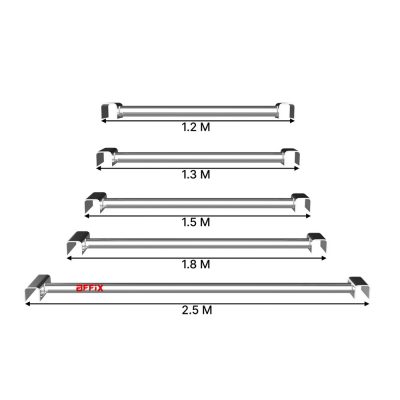

Tie Rods

-

Toe Board Clamp

-

Universal Clamps

-

Waller Plate

-

Water Barrier Nut

-

Wing Nut

-

Wooden Planks

Applications

Cuplock System Scaffolding Germany

Cuplock system scaffolding has become an essential solution for construction and industrial projects across Germany, offering unmatched efficiency, safety, and adaptability. Its unique cup-and-head locking mechanism ensures rapid assembly while maintaining structural stability, making it suitable for complex, high-rise, and large-scale applications. Cuplock system scaffolding provides a versatile platform that meets modern construction demands, combining modular design, durability, and high load-bearing capacity. Professionals rely on Cuplock Scaffolding System Germany for projects requiring quick deployment, robust support, and compliance with rigorous safety standards. Affix Scaffolding delivers high-quality Cuplock System Germany to meet these critical operational requirements.

What is Cuplock System Scaffolding?

Cuplock system scaffolding is a versatile and efficient form of modular scaffolding widely used across construction, industrial, and maintenance projects in Germany. Its distinctive design is based on a cup-and-head locking mechanism that allows scaffolding components to be securely connected with minimal effort, providing stability, strength, and flexibility. Unlike traditional scaffolding systems that require bolts, nuts, or clamps, Cuplock Scaffolding System Germany offers rapid assembly and disassembly, reducing labor time while ensuring a safe working platform for personnel at varying heights.

Construction and Materials

-

High-quality steel: Most Cuplock systems are constructed using high-strength, galvanized steel, offering durability, corrosion resistance, and long-term reliability.

-

Cup-and-head joints: These joints are engineered to lock horizontals and verticals precisely, providing a secure structural connection without additional fasteners.

-

Modular components: The system includes standards (verticals), ledgers (horizontals), transoms, and diagonal braces, enabling flexible configurations for different project needs.

The combination of high-quality materials and precise construction ensures that Cuplock scaffolding maintains stability, even under heavy loads or in demanding environmental conditions.

Types and Variations

Cuplock system scaffolding can be customized for multiple applications, with various types and configurations available:

-

Standard Cuplock scaffolding: Provides a reliable platform for general construction, maintenance, and industrial tasks.

-

Heavy-duty Cuplock scaffolding: Designed to support higher load capacities for large-scale or high-rise projects.

-

Mobile Cuplock scaffolding: Incorporates wheels and casters for portability across site locations without compromising structural integrity.

-

Adjustable Cuplock systems: Include height-adjustable components to accommodate different working elevations.

The modularity of Cuplock System Germany allows project managers to design scaffolding structures that precisely meet site-specific requirements, reducing material waste and labor costs.

Applications

Cuplock scaffolding is highly adaptable, making it suitable for a wide range of applications:

-

Construction projects: High-rise buildings, commercial structures, and residential complexes benefit from quick assembly and structural stability.

-

Industrial maintenance: Plants, factories, and warehouses require scaffolding systems that can be rapidly installed and safely support heavy loads.

-

Events and temporary structures: The modularity of Cuplock scaffolding allows for temporary stages, platforms, or frameworks for exhibitions and events.

-

Bridges and infrastructure projects: High-strength components and adaptable configurations make Cuplock scaffolding ideal for complex infrastructure work.

The adaptability ensures that Cuplock scaffolding provides reliable support in both vertical and horizontal constructions, making it a versatile choice for diverse operational scenarios.

Key Advantages of Cuplock System Design

-

Rapid assembly and disassembly: The cup-and-head locking system allows components to be connected and disconnected quickly, reducing setup time significantly.

-

High load-bearing capacity: Cuplock scaffolding supports heavy loads, including multiple workers, equipment, and materials, without compromising safety.

-

Modular flexibility: Components can be configured in multiple layouts, enabling custom solutions for specific project demands.

-

Safety and stability: Precision-engineered joints and braces ensure that the scaffolding remains rigid and secure under operational stress.

The combination of these advantages allows construction teams to operate efficiently while adhering to rigorous safety standards.

Integration with Other Systems

Cuplock scaffolding can be integrated with additional platforms, planks, and safety accessories:

-

Work platforms: Adjustable planks and platforms provide stable surfaces for prolonged tasks.

-

Guardrails and toe boards: Enhance safety for elevated work areas.

-

Diagonal bracing: Improves overall structural rigidity, especially for taller constructions.

This integration ensures that Cuplock system scaffolding provides not only structural support but also a safe working environment for professionals across Germany.

Why is Cuplock System Scaffolding Popular?

Cuplock system scaffolding has gained widespread adoption across construction, industrial, and maintenance sectors in Germany due to its efficiency, versatility, and robust design. Its unique engineering and modular design address the operational demands of modern projects, making it a preferred choice for professionals seeking safe, adaptable, and reliable elevated access solutions. Several factors contribute to the popularity of the Cuplock Scaffolding System in Germany, reflecting its practical advantages over traditional scaffolding systems.

1. Rapid Assembly and Disassembly

-

Cup-and-head mechanism: Enables quick, secure connections without the need for bolts or clamps.

-

Labor efficiency: Reduces setup and dismantling time significantly, allowing projects to proceed faster.

-

Minimal tools required: Simplifies the installation process, reducing labor costs and potential errors.

The speed and simplicity of assembling Cuplock scaffolding make it ideal for projects where time efficiency is critical, allowing teams to focus on other operational tasks.

2. High Load-Bearing Capacity

-

Heavy-duty construction: Galvanized steel components support substantial weight, including personnel and equipment.

-

Stability under stress: Cup-and-head joints distribute loads evenly, minimizing the risk of collapse.

-

Versatile configurations: Can support both vertical and horizontal loads for multi-level structures.

This strong load capacity ensures safe operation on construction sites, industrial facilities, and complex installations, giving professionals confidence in their elevated work platforms.

3. Modular Flexibility

-

Customizable layouts: Components can be combined in different ways to create scaffolding structures of varying heights and widths.

-

Expandable system: Additional standards, ledgers, and braces can be added as project requirements change.

-

Adaptable for different applications: Suitable for residential, commercial, and industrial construction.

The modular design allows Cuplock scaffolding to adapt to project-specific needs, reducing material waste and enhancing operational efficiency.

4. Enhanced Safety Features

-

Precision-engineered joints: Ensure secure locking and reduce the risk of structural failure.

-

Stable base plates: Provide secure footing on uneven surfaces.

-

Guardrails and toe boards integration: Protect workers from falls during elevated operations.

Safety is a primary consideration, and Cuplock System Germany provides a framework that meets or exceeds German workplace safety standards.

5. Durability and Longevity

-

Galvanized steel construction: Offers excellent corrosion resistance and weather protection.

-

Heavy-duty design: Withstands repeated assembly, disassembly, and long-term use without deformation.

-

Low maintenance requirements: Minimal upkeep needed, ensuring consistent performance over the years.

The durability of Cuplock scaffolding ensures that investments in these systems are cost-effective, providing long-term value for professional teams.

6. Adaptability Across Project Types

-

High-rise construction: Supports multiple levels and complex geometries.

-

Industrial maintenance: Provides safe platforms for heavy equipment access and machinery work.

-

Infrastructure projects: Bridges, tunnels, and large-scale civil projects benefit from rapid deployment and structural integrity.

-

Temporary structures: Can be used for event staging or temporary elevated platforms.

The adaptability of the Cuplock system scaffolding allows it to serve multiple sectors effectively, increasing its practical appeal.

7. Space and Material Efficiency

-

Compact storage: Components can be stacked and stored easily when not in use.

-

Optimized material use: Modular design allows customization, reducing unnecessary material deployment.

-

Easy transportation: Lightweight and stackable components simplify logistics on-site.

Efficient use of space and materials reduces costs and simplifies site management for German construction projects.

8. Compliance with Standards

-

DIN and EN certifications: Ensure compliance with German and European safety regulations.

-

Engineered for load and stability: Meets stringent construction requirements for structural reliability.

-

Professional-grade quality: Guarantees that the scaffolding is suitable for both public and industrial applications.

Regulatory compliance is essential in Germany, and Cuplock scaffolding consistently meets these requirements, reinforcing its popularity among professionals.

9. Cost-Effectiveness

-

Reduced labor costs: Faster assembly lowers manpower requirements.

-

Long-lasting investment: Durability reduces the frequency of replacements.

-

Versatility reduces inventory needs: Multi-purpose configurations eliminate the need for multiple scaffolding systems.

Cost-efficiency, combined with safety and adaptability, makes Cuplock scaffolding a practical investment for construction firms and industrial operators.

10. Comparison with Other Scaffolding Systems

-

Tube-and-clamp scaffolding: Requires more time and labor for assembly; less modular.

-

Frame scaffolding: Limited flexibility for irregular structures.

-

Cuplock scaffolding: Combines rapid installation, load-bearing capacity, and modular adaptability, providing superior operational efficiency and safety.

Professionals increasingly prefer Cuplock System Germany because it addresses the limitations of alternative scaffolding systems while maintaining high standards of performance and safety.

The combination of speed, strength, safety, modular flexibility, and cost-effectiveness explains why Cuplock system scaffolding is widely adopted across Germany. Its design supports diverse construction, industrial, and infrastructure projects, offering professionals reliable platforms for elevated work with confidence and efficiency. Affix Scaffolding provides a premium Cuplock Scaffolding System engineered to meet these operational and regulatory demands.

Benefits of Cuplock System Scaffolding

Cuplock system scaffolding is widely recognized for its efficiency, safety, and adaptability, making it a preferred solution for construction, industrial, and maintenance projects across Germany. Its innovative design and modular components provide numerous benefits that enhance operational productivity, reduce costs, and improve overall worksite safety. Below are the primary advantages of using Cuplock System Germany.

1. Rapid Installation

-

Cup-and-head locking system: Allows horizontal and vertical components to be securely connected without the need for bolts or additional tools.

-

Reduced assembly time: Significantly cuts labor hours required for setup and dismantling.

-

Minimal equipment needed: Simplifies logistics and allows teams to deploy scaffolding quickly across multiple sites.

Rapid installation ensures that projects stay on schedule and minimizes downtime, which is particularly important for large-scale or time-sensitive operations.

2. High Load-Bearing Capacity

-

Heavy-duty steel components: Provide exceptional structural strength, supporting multiple workers, tools, and materials.

-

Even load distribution: Cup-and-head joints distribute weight uniformly, minimizing stress points and enhancing stability.

-

Multi-level use: Supports elevated work platforms safely across varying heights.

The high load capacity ensures a reliable working environment, even for demanding industrial and construction applications.

3. Modular Versatility

-

Flexible configurations: Components can be combined in numerous ways to accommodate different site layouts and project requirements.

-

Expandable design: Additional standards, ledgers, and braces can be added to adjust scaffolding height or width.

-

Adaptable across sectors: Suitable for construction, industrial maintenance, infrastructure, and temporary structures.

Modular versatility allows professionals to customize scaffolding to suit site-specific conditions, reducing material waste and enhancing operational efficiency.

4. Enhanced Safety

-

Precision-engineered joints: Ensure secure locking and prevent accidental disassembly.

-

Stable base plates: Maintain balance on uneven surfaces.

-

Integration with guardrails and toe boards: Provides additional protection for workers on elevated platforms.

Safety is a critical advantage, making the Cuplock System Germany compliant with German and European workplace regulations.

5. Durability and Longevity

-

Galvanized steel construction: Offers excellent resistance to corrosion, rust, and environmental damage.

-

Robust design: Withstands repeated assembly, disassembly, and high-load operations without deformation.

-

Low maintenance requirements: Minimal upkeep needed for long-term reliability.

Durable construction ensures that investments in Cuplock scaffolding provide long-term value for professional teams.

6. Efficient Use of Space and Materials

-

Compact storage: Components can be stacked or nested when not in use, saving space on-site.

-

Optimized material usage: Modular design ensures materials are used efficiently, reducing waste.

-

Portability: Lightweight, stackable components simplify transport across project locations.

Efficient storage and transportation reduce logistical challenges and lower overall project costs.

7. Cost-Effectiveness

-

Reduced labor costs: Faster setup and dismantling decrease manpower requirements.

-

Long-term investment: Durability and versatility minimize the need for frequent replacements.

-

Reduced inventory needs: Multi-purpose configurations eliminate the requirement for multiple scaffolding systems.

The combination of time savings, durability, and adaptability translates into significant cost benefits for construction and industrial projects.

8. Adaptable for Various Project Types

-

High-rise construction: Supports multi-level structures with stable platforms.

-

Industrial maintenance: Provides secure access to machinery, tanks, and elevated equipment.

-

Infrastructure projects: Bridges, tunnels, and other large-scale civil projects benefit from easy deployment and structural integrity.

-

Temporary installations: Can be used for stages, event platforms, and temporary elevated work areas.

Cuplock system scaffolding accommodates diverse operational needs, enhancing its practical value across multiple sectors.

9. Compliance with Standards

-

DIN and EN certified: Meets German and European safety regulations.

-

Engineered reliability: Designed to support weight and structural loads safely.

-

Professional-grade quality: Ensures suitability for both industrial and construction applications.

Regulatory compliance is essential for professional operations, and Cuplock scaffolding consistently meets these requirements, reinforcing trust among project managers.

10. Long-Term Operational Efficiency

-

Quick deployment: Reduces project delays and improves overall workflow.

-

Safe and stable platforms: Minimize workplace accidents and associated costs.

-

Reusable components: Allow multiple projects to benefit from the same scaffolding investment.

Long-term efficiency enhances project timelines, safety, and budget management, making Cuplock System Germany an ideal solution for professional teams.

Cuplock system scaffolding offers a comprehensive set of benefits, including rapid installation, high load capacity, modular versatility, safety, durability, cost-effectiveness, and adaptability. These advantages make it a reliable choice for professionals across construction, industrial, and maintenance projects in Germany. Affix Scaffolding provides high-quality Cuplock System Scaffolding Germany to maximize these operational benefits for every project.

Features of Cuplock System Scaffolding

Cuplock system scaffolding offers a range of innovative features that make it a reliable, versatile, and efficient solution for construction, industrial, and maintenance projects in Germany. Its engineering and modular design provide structural integrity, safety, and flexibility, allowing professionals to deploy scaffolding systems across a variety of applications with confidence. Below are the key features of the Cuplock System Germany and their practical significance.

1. Cup-and-Head Locking Mechanism

-

Secure connections: The cup-and-head system locks horizontal ledgers into vertical standards without bolts, ensuring rapid and stable assembly.

-

Ease of use: Components can be connected and disconnected quickly, reducing labor time.

-

Structural integrity: The locking mechanism distributes loads evenly, enhancing the overall stability of the scaffolding structure.

This feature is fundamental to the efficiency and reliability of Cuplock scaffolding, enabling safe and fast deployment.

2. Modular Components

-

Standards (vertical posts): Provide vertical support and anchor points for horizontal ledgers.

-

Ledgers (horizontal bars): Connect standards to create a secure frame.

-

Transoms and braces: Offer lateral support and maintain rigidity across multiple levels.

-

Decking and platforms: Serve as stable working surfaces for personnel and equipment.

Modular design allows customization of scaffolding layouts to match project requirements, providing flexibility for different heights, widths, and configurations.

3. Adjustable Height

-

Multiple levels: Components can be added or removed to achieve desired working heights.

-

Versatile applications: Suitable for high-rise construction, industrial maintenance, and temporary structures.

-

Precision alignment: Adjustable standards and transoms maintain stability and balance across elevated platforms.

Height adjustability ensures that Cuplock System Germany can accommodate diverse project needs, from low-level maintenance to multi-story construction tasks.

4. Corrosion-Resistant Steel Construction

-

Galvanized steel components: Provide excellent resistance against rust, weathering, and environmental exposure.

-

Long-lasting durability: Maintains structural integrity even in harsh working conditions.

-

Minimal maintenance: Ensures consistent performance over repeated assembly and disassembly cycles.

Corrosion resistance increases the lifespan of the scaffolding, reducing replacement costs and providing long-term reliability.

5. Ease of Transport and Storage

-

Stackable components: Modular standards, ledgers, and platforms can be efficiently stacked for storage.

-

Lightweight sections: Facilitate transportation across construction sites.

-

Compact logistics: Reduces space requirements for inventory and shipping.

Transportable and easy-to-store components allow projects to operate more efficiently, especially across multiple work sites.

6. Integration with Safety Accessories

-

Guardrails and toe boards: Can be easily attached to elevated platforms to prevent falls.

-

Diagonal braces: Enhance structural rigidity, especially for taller scaffolding structures.

-

Secure base plates: Distribute loads and provide stability on uneven surfaces.

Safety accessories integrated with Cuplock scaffolding ensure compliance with German and European workplace regulations, minimizing the risk of accidents.

7. Compatibility with Multi-Level Configurations

-

Stackable standards: Support multiple tiers for high-rise projects.

-

Interlocking ledgers: Maintain alignment across all levels, ensuring stability.

-

Adjustable decking: Provides consistent working surfaces on each level.

Multi-level compatibility allows Cuplock scaffolding to be used for complex construction projects and high-rise structures efficiently.

8. Versatility Across Project Types

-

Construction applications: Suitable for residential, commercial, and industrial construction projects.

-

Industrial maintenance: Provides access to machinery, tanks, and elevated equipment.

-

Temporary structures: Can be adapted for event platforms, exhibition stages, and other short-term installations.

The versatility of the Cuplock System Germany enhances operational efficiency and reduces the need for multiple scaffolding systems.

9. High Load-Bearing Capacity

-

Reinforced joints and components: Support heavy loads of personnel, equipment, and materials.

-

Even weight distribution: Cup-and-head locking system ensures stability under stress.

-

Reliable support for multi-level structures: Ensures safe elevated work across all tiers.

High load-bearing capacity makes Cuplock scaffolding suitable for industrial and large-scale construction projects.

10. Compliance with Professional Standards

-

DIN and EN certified: Meets German and European safety and performance regulations.

-

Engineered for reliability: Designed to maintain structural integrity under rigorous working conditions.

-

Professional-grade quality: Ensures suitability for both industrial and construction applications.

Adherence to professional standards guarantees that Cuplock scaffolding meets safety, durability, and operational expectations required by German construction and industrial professionals.

The combination of these features—cup-and-head locking mechanism, modular components, adjustable height, corrosion-resistant steel, portability, safety integration, multi-level capability, versatility, load capacity, and regulatory compliance—makes Cuplock system scaffolding a superior choice for professional projects in Germany. Affix Scaffolding supplies high-quality Cuplock System Germany, engineered to provide efficiency, safety, and adaptability for all construction and industrial applications.

Tips to Follow While Looking for Cuplock System Scaffolding

Selecting the right Cuplock system scaffolding in Germany requires careful consideration to ensure safety, durability, and operational efficiency. With various suppliers and products available, understanding key factors helps professionals make informed decisions. Below are essential tips to follow while purchasing the Cuplock System Germany.

1. Check for Certification and Compliance

-

DIN and EN standards: Ensure the scaffolding complies with German and European safety regulations.

-

Load testing certifications: Verify that the system has been tested to handle designated weight capacities.

-

Quality assurance: Certifications indicate that components meet rigorous performance and safety criteria.

Choosing a certified Cuplock system guarantees compliance with regulations, providing confidence in workplace safety.

2. Evaluate Material Quality

-

High-strength galvanized steel: Ensures corrosion resistance and long-term durability.

-

Reinforced components: Standards, ledgers, and transoms should be designed for heavy-duty use.

-

Consistent manufacturing: Look for uniformity in dimensions and welding quality for reliable assembly.

Superior material quality minimizes maintenance, enhances safety, and extends the scaffolding’s lifespan.

3. Consider Load Capacity

-

Understand project requirements: Determine the maximum weight the scaffolding will need to support, including workers and equipment.

-

Heavy-duty options: For industrial or high-rise projects, select components designed for higher load capacities.

-

Multi-level safety: Ensure the system can handle combined loads across multiple tiers without compromising stability.

Accurate assessment of load capacity ensures safe operations and prevents accidents caused by overloading.

4. Assess Modularity and Flexibility

-

Component compatibility: Check that standards, ledgers, transoms, and braces can be combined for varied layouts.

-

Expandable design: Select systems that can be extended or reduced as project needs change.

-

Versatile applications: Ensure the system is adaptable for different projects, from construction to industrial maintenance.

Flexible scaffolding allows professionals to tailor structures to site-specific conditions efficiently.

5. Inspect Safety Features

-

Cup-and-head locking mechanism: Verify smooth operation and secure connections.

-

Stable base plates: Ensure the system provides a secure footing on uneven surfaces.

-

Integration of guardrails and toe boards: Adds protection for workers during elevated tasks.

Prioritizing safety features ensures compliance and protects personnel working on the scaffolding.

6. Evaluate Supplier Reliability

-

Reputation and experience: Choose suppliers known for consistent quality and reliable delivery.

-

Warranty and after-sales support: Confirm availability of technical support and replacement components.

-

Site assistance: Some suppliers provide guidance for assembly or inspections, adding value.

Reliable suppliers ensure consistent product quality and assist in maintaining safety standards on-site.

7. Examine Assembly and Disassembly Ease

-

Quick-connect design: Components should lock securely without requiring extensive tools.

-

User-friendly instructions: Clear guidelines facilitate faster deployment and minimize errors.

-

Time efficiency: Rapid assembly reduces labor costs and supports project timelines.

Ease of assembly is crucial for projects with tight schedules or frequent scaffold relocation requirements.

8. Check for Corrosion Resistance

-

Galvanized or treated steel: Prevents rust and extends service life.

-

Environmental suitability: Consider systems that withstand humidity, rain, and outdoor exposure.

-

Low maintenance: Minimizes downtime and reduces cost over repeated use.

Corrosion-resistant scaffolding maintains structural integrity and ensures long-term reliability in German weather conditions.

9. Assess Storage and Transport Considerations

-

Stackable components: Efficient storage saves warehouse space.

-

Lightweight sections: Simplify handling and transportation across sites.

-

Compact packaging: Reduces logistical challenges for delivery and on-site deployment.

Easy storage and transport enhance operational efficiency and reduce project overhead.

10. Analyze Cost and Value

-

Balance upfront cost with long-term durability: Cheaper systems may require frequent replacement, while high-quality components provide long-term savings.

-

Consider lifecycle cost: Include assembly labor, maintenance, and replacement parts in the overall budget.

-

Multi-project usability: Modular, durable scaffolding offers higher value when used across multiple projects.

Evaluating cost alongside durability, safety, and flexibility ensures a worthwhile investment in Cuplock System Germany.

By following these tips—checking certification, material quality, load capacity, modularity, safety features, supplier reliability, assembly ease, corrosion resistance, storage efficiency, and overall cost—professionals can select a Cuplock scaffolding system that meets operational needs safely and effectively. Affix Scaffolding offers high-quality Cuplock System Germany with robust design, certified materials, and reliable support, ensuring optimal performance for diverse projects.

Why Choose Affix Scaffolding?

Affix Scaffolding has established itself as a trusted provider of premium Cuplock system scaffolding in Germany. The company focuses on delivering high-quality, reliable, and versatile scaffolding solutions that meet the safety and operational requirements of construction, industrial, and maintenance projects. By prioritizing quality, customer service, and technical support, Affix Scaffolding ensures that professionals receive scaffolding systems that perform efficiently while complying with stringent standards. The following points highlight the key reasons to choose Affix Scaffolding for the Cuplock System Germany.

1. Superior Product Quality

-

High-grade materials: All components, including standards, ledgers, transoms, and platforms, are manufactured from galvanized steel to ensure strength, corrosion resistance, and durability.

-

Precision engineering: Cup-and-head locking mechanisms and modular components are engineered for secure connections and consistent alignment.

-

Durable design: Products are built to withstand heavy loads, repeated assembly and disassembly, and harsh environmental conditions.

Affix Scaffolding prioritizes quality to guarantee long-lasting scaffolding solutions that professionals can rely on for demanding projects.

2. Compliance with Safety Standards

-

Certified systems: All Cuplock scaffolding meets DIN and EN standards, ensuring compliance with German and European safety regulations.

-

Rigorous testing: Components undergo load and stress testing to confirm stability, safety, and performance.

-

Safety integration: Guardrails, toe boards, and stable base plates are designed for seamless integration, providing maximum protection for workers.

By offering certified and tested scaffolding, Affix Scaffolding reduces workplace risk and ensures legal compliance on construction and industrial sites.

3. Versatility Across Applications

-

Construction projects: Suitable for residential, commercial, and industrial construction needs, including high-rise structures.

-

Industrial maintenance: Provides secure platforms for machinery, equipment, and elevated access points.

-

Temporary structures: Adaptable for events, stages, or short-term installations without compromising safety.

-

Customizable configurations: Modular components allow scaffolding layouts to be tailored for specific project requirements.

The versatility of the Cuplock System Germany provided by Affix Scaffolding allows professionals to address diverse operational needs with a single scaffolding solution.

4. Ease of Assembly and Dismantling

-

Rapid deployment: Cup-and-head locking system allows fast and secure connections without extensive tools.

-

Reduced labor costs: Quick assembly minimizes workforce requirements, saving time and operational expenses.

-

Clear instructions: Affix Scaffolding provides detailed guidelines to ensure proper installation and safe use.

Efficiency in assembly and dismantling ensures projects stay on schedule while maintaining safety and operational productivity.

5. Exceptional Load Capacity

-

Heavy-duty construction: Supports multiple workers, equipment, and materials safely.

-

Stable multi-level platforms: Designed to maintain balance and structural integrity across all tiers.

-

Even weight distribution: Cup-and-head connections ensure stability under heavy loads.

Affix Scaffolding ensures that all Cuplock systems provide reliable support for challenging tasks, making them suitable for large-scale and high-rise projects.

6. Long-Term Durability

-

Corrosion-resistant galvanized steel: Protects against rust and environmental damage, extending the lifespan of components.

-

Low maintenance: Durable materials reduce the need for frequent repairs or replacements.

-

Reliable performance: Scaffolding maintains structural integrity through repeated use across multiple projects.

Long-term durability ensures a valuable investment, reducing operational costs and increasing return on investment.

7. Comprehensive Customer Support

-

Technical guidance: Assistance in selecting appropriate configurations and load capacities.

-

After-sales support: Replacement components and maintenance advice are readily available.

-

Responsive service: Affix Scaffolding ensures timely support for all professional inquiries and operational needs.

Strong customer support ensures that projects using the Cuplock System Germany run smoothly, reducing downtime and operational challenges.

8. Efficient Storage and Transport

-

Compact design: Modular components are stackable for easy storage.

-

Portable sections: Lightweight and transportable, simplifying movement across multiple sites.

-

Optimized logistics: Affix Scaffolding provides solutions that enhance operational efficiency on-site.

Ease of storage and transport improves project management and reduces logistical costs.

9. Cost-Effective Solutions

-

Long-term value: Durable and versatile systems reduce replacement frequency.

-

Labor savings: Quick assembly and disassembly minimize workforce costs.

-

Adaptability reduces inventory: One system can serve multiple projects, cutting material expenditure.

Affix Scaffolding ensures that investing in the Cuplock System Germany delivers both operational efficiency and financial benefits for professional teams.

10. Commitment to Professional Excellence

-

Industry expertise: Focused on delivering scaffolding solutions engineered for professional standards.

-

Innovation: Continually improving products for enhanced safety, durability, and efficiency.

-

Reliability: Affix Scaffolding stands behind every system supplied, ensuring consistent performance for demanding projects.

Affix Scaffolding combines quality, safety, versatility, and support to provide the Cuplock System Germany that meets the highest professional expectations.

By choosing Affix Scaffolding, professionals in Germany can access high-quality Cuplock scaffolding systems that provide durability, safety, adaptability, and cost-efficiency. The company’s commitment to excellence ensures that every project benefits from reliable and versatile scaffolding solutions designed to meet the rigorous demands of construction and industrial applications.

Cuplock System Scaffolding FAQs

1. What is Cuplock system scaffolding?

Cuplock system scaffolding in Germany is a modular scaffolding system with a unique cup-and-head locking mechanism. It allows quick assembly of vertical standards and horizontal ledgers, providing stable, versatile, and safe platforms suitable for construction, industrial, and maintenance projects across various heights and configurations.

2. What types of Cuplock scaffolding are available?

Cuplock scaffolding includes standard configurations, heavy-duty systems, multi-level platforms, and adjustable height setups. Components like standards, ledgers, transoms, and decking can be combined to create customized layouts. This flexibility ensures suitability for construction, industrial maintenance, infrastructure projects, and temporary elevated structures.

3. Is Cuplock scaffolding safe for high-rise projects?

Yes. Cuplock System Germany features reinforced steel components and precision-engineered cup-and-head connections. Multi-level platforms maintain stability, while guardrails and base plates enhance worker safety. Compliance with DIN and EN standards ensures safe operation even in elevated construction and industrial applications.

4. How durable is Cuplock scaffolding?

Cuplock scaffolding is constructed from galvanized steel, providing excellent resistance to corrosion, rust, and environmental wear. Components are engineered to withstand repeated assembly, heavy loads, and harsh conditions, offering long-term durability and reliable performance across multiple projects in Germany.

5. Can Cuplock scaffolding be customized?

Yes. Its modular design allows professionals to adjust height, width, and configuration. Additional standards, ledgers, and braces can be added to meet specific project requirements. This adaptability makes Cuplock System Germany suitable for varied applications, from industrial maintenance to complex construction layouts.

6. What should I check before purchasing Cuplock scaffolding?

Verify certifications (DIN and EN), material quality, load capacity, modularity, corrosion resistance, supplier reliability, and ease of assembly. Ensuring these factors helps maintain safety, operational efficiency, and long-term performance while providing the best value for construction or industrial projects.

7. How easy is it to assemble and dismantle Cuplock scaffolding?

Cuplock scaffolding features a cup-and-head locking system that allows rapid assembly without bolts or specialized tools. Components are designed for quick connections and disassembly, reducing labor time, minimizing errors, and improving efficiency for projects requiring frequent relocation or reconfiguration.

8. Can Cuplock scaffolding support heavy equipment?

Yes. Reinforced standards and ledgers, combined with evenly distributed weight through cup-and-head joints, allow Cuplock scaffolding to handle substantial loads. Multi-level platforms maintain stability under heavy materials and personnel, making them suitable for demanding industrial and construction environments.

9. Is Cuplock scaffolding resistant to corrosion?

Yes. Components are typically galvanized or treated steel, providing excellent resistance to rust, moisture, and environmental exposure. This corrosion-resistant construction ensures long-lasting performance, low maintenance requirements, and reliable safety for projects in outdoor or harsh conditions.

10. How does Affix Scaffolding support Cuplock system users?

Affix Scaffolding offers certified Cuplock System Germany with high-quality components, technical guidance, and after-sales support. Assistance includes configuration recommendations, replacement parts, and assembly advice, ensuring professional teams have safe, durable, and efficient scaffolding solutions for diverse construction and industrial applications.