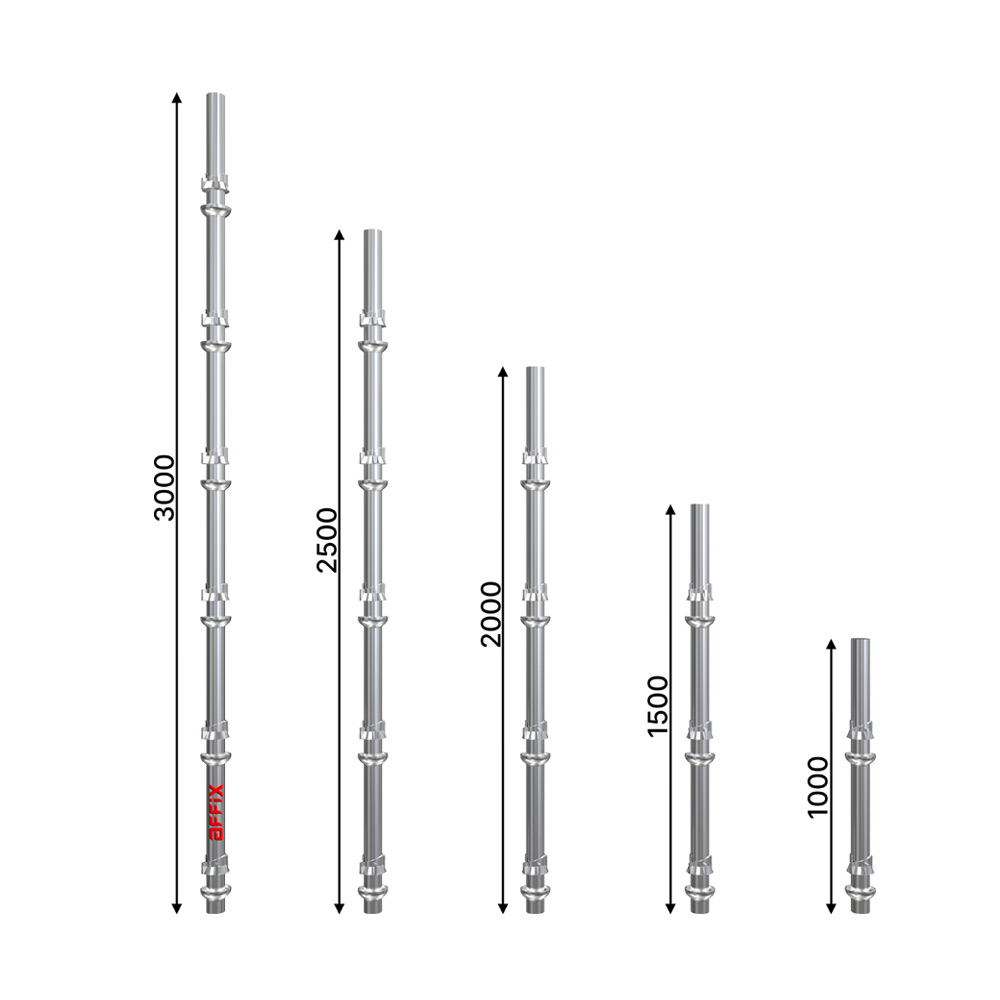

Cuplock Standard

Model No.- FCC01

- Fabricated out of 48.3mm OD x 3.2mm thick high grade steel tube.

- All standards have the lower part of the cups at 0.5m intervals with captive rotating top-cups securing up to 4 components.

- The lowest bottom cup is welded at 80mm from the bottom end of the standard and the highest bottom cup is welded at 420 from the upper end of the standard.

- Every Standard is joined vertically using a Spigot

Cuplock Standard Europe

In modern European construction, scaffolding systems are fundamental for ensuring worker safety, operational efficiency, and structural support. Among these systems, Cuplock Standard Europe has emerged as a preferred solution, combining modular design, rapid assembly, and compliance with stringent EN and EU regulations. Its unique locking mechanism and durable components provide stability and versatility across diverse construction environments. For scaffolding contractors, site managers, and procurement officers, understanding the specifications, applications, and regulatory compliance of Cuplock systems is critical. This ensures safe platforms, reduces installation time, and supports long-term operational reliability on commercial, industrial, and residential projects throughout Europe.

What is Cuplock Scaffolding?

Cuplock scaffolding is a modular system designed for versatility, strength, and rapid assembly, widely used in European construction projects. Unlike traditional tube-and-coupler scaffolding, which requires individual connections, Cuplock utilizes a unique cup-and-lock mechanism that allows quick, secure connections between standards, ledgers, and transoms. This design reduces assembly time, enhances stability, and simplifies inspection procedures, making it a reliable choice for commercial, industrial, and residential projects.

Definition and Purpose

Cuplock scaffolding serves to create temporary yet highly stable platforms for workers, materials, and equipment. Its primary purposes include:

-

Providing safe working platforms at varying heights.

-

Supporting heavy loads and ensuring even distribution across the scaffold.

-

Allowing rapid assembly and disassembly to optimize construction schedules.

-

Maintaining compliance with European safety and quality regulations.

Comparison with Other Scaffolding Systems

-

Tube-and-Coupler Scaffolding: Requires manual fitting of each component, resulting in longer assembly times.

-

Frame Scaffolding: Offers simplicity but limited versatility and adjustability for complex layouts.

-

Cuplock Scaffolding: Combines speed, modularity, and adaptability, providing secure connections at every junction with minimal tools.

Material and Durability Considerations

High-quality materials are essential for Cuplock scaffolding to ensure durability and long-term performance. Key considerations include:

-

Corrosion Resistance: Components are typically galvanised or made from high-grade steel to withstand moisture, humidity, and other environmental factors.

-

Load-Bearing Strength: Designed to meet EN and EU standards for vertical and horizontal load capacity.

-

Wear Resistance: Locking cups and wedges are precision-engineered to endure repeated assembly and disassembly without degradation.

-

Longevity: Durable materials reduce maintenance requirements and extend the life cycle of the scaffolding system.

Key Components of Cuplock Scaffolding

-

Standards: Vertical posts that bear the main structural load.

-

Ledgers: Horizontal elements connecting standards and providing lateral support.

-

Transoms: Cross-members supporting scaffolding boards and distributing load.

-

Cuplock Nodes: Cup-and-wedge connectors at each intersection of standards and ledgers for secure fastening.

-

Base Plates: Stabilize standards and distribute loads onto the foundation surface.

-

Scaffold Boards: Platforms installed on transoms, providing a secure work surface.

-

Guardrails and Toe Boards: Safety features ensuring worker protection on elevated platforms.

-

Bracing Components: Diagonal members enhance rigidity and overall structural stability.

Advantages of Component Integration

Cuplock’s modular components allow seamless integration into complex scaffolding designs, supporting multi-level platforms, cantilevered structures, and varying heights. The standardized connection points simplify assembly and inspection, ensuring consistent safety and compliance across all levels of the scaffold.

Design Flexibility

Cuplock scaffolding can be adapted for irregular surfaces, varying building geometries, and dynamic construction requirements. Its modularity enables rapid adjustment, expansion, or repositioning without compromising stability. This adaptability is particularly valuable in European construction projects, where regulatory compliance and operational efficiency are paramount.

Operational Efficiency

The cup-and-lock mechanism significantly reduces assembly and dismantling times compared with traditional systems. Workers can connect components securely using minimal tools, while standardized parts reduce errors and facilitate maintenance. This efficiency translates to cost savings, faster project completion, and enhanced worker safety.

European Standards for Cuplock Systems

Compliance with European regulations is a cornerstone of safe and reliable scaffolding. Cuplock Standard Europe systems are specifically designed to meet stringent EN and EU safety standards, providing construction professionals with confidence in structural integrity, load-bearing capacity, and operational reliability. Adherence to these standards ensures legal compliance, minimizes risks, and promotes efficient project management across commercial, industrial, and residential projects.

EN and EU Regulatory Compliance

European scaffolding standards, including EN 12811 and EN 74, define requirements for scaffolding design, assembly, and safety performance. Cuplock systems are engineered to comply with these standards, which cover:

-

Structural Load Capacity: Ensuring vertical and horizontal loads are safely supported without deformation.

-

Stability and Rigidity: Maintaining scaffold integrity under dynamic construction loads and environmental factors.

-

Material Quality: Specifying high-strength, corrosion-resistant metals for long-term durability.

-

Assembly Safety: Requiring standardized, secure connections between components to prevent accidents.

-

Inspection and Maintenance: Outlining procedures for regular checks to ensure ongoing compliance and safety.

Certification Requirements

Certified Cuplock Standard Supplier Europe products provide documentation verifying compliance with European safety standards. These certifications confirm that each component has undergone rigorous testing for:

-

Load-bearing performance under both static and dynamic conditions.

-

Resistance to environmental factors, including corrosion and temperature variation.

-

Mechanical reliability of cup-and-wedge locking mechanisms.

-

Compatibility with other certified scaffolding components to ensure structural cohesion.

-

Safety under repeated assembly and disassembly cycles.

Importance of Standardized Components

Using standardized Cuplock components is crucial for consistent safety and efficiency. Non-standard or uncertified components can compromise scaffold stability, increase the risk of accidents, and result in non-compliance with European regulations. Benefits of standardized components include:

-

Uniform connection points for reliable assembly.

-

Interchangeable parts for flexible scaffolding configurations.

-

Simplified inspection and maintenance routines.

-

Reduced the likelihood of structural failure during high-stress operations.

-

Compatibility with certified accessories such as guardrails, toe boards, and base plates.

Safety Considerations under European Standards

European standards prioritize worker safety, requiring that all scaffolding systems maintain structural integrity under maximum load conditions. Cuplock systems address these safety considerations through:

-

Secure cup-and-wedge connections prevent accidental disengagement.

-

Load-distribution design minimizing stress points on standards and ledgers.

-

Integration with guardrails, braces, and platforms to ensure fall protection.

-

Corrosion-resistant materials maintain performance in outdoor and industrial environments.

-

Clear marking of load capacities and component certifications for inspection compliance.

Inspection and Documentation

Regular inspections are mandated under European scaffolding regulations to ensure ongoing compliance. Cuplock systems simplify inspection processes due to their standardized design and clear connection points. Key inspection practices include:

-

Verifying all cup-and-wedge connections are fully engaged and secure.

-

Checking for wear, deformation, or corrosion on standards, ledgers, and transoms.

-

Ensuring base plates are correctly positioned and load-bearing surfaces are level.

-

Documenting maintenance, repairs, and replacements to maintain certification records.

-

Confirming that all components remain compliant with EN 12811 and EN 74 requirements.

Advantages of Compliance

Adhering to European standards when using Cuplock Standard Europe provides tangible operational benefits:

-

Legal assurance and reduced liability for construction companies.

-

Enhanced worker confidence due to verified structural integrity.

-

Optimized scaffolding design with modular, compliant components.

-

Efficient project timelines with minimal downtime due to component failure.

-

Long-term durability reduces costs associated with replacements or non-compliance penalties.

Key Features of Cuplock Standard Europe

Cuplock Standard Europe scaffolding systems are designed to provide strength, flexibility, and efficiency for construction projects across Europe. Their modular design, superior materials, and standardized components make them suitable for a wide range of applications, from residential renovations to large commercial developments. Understanding the core features of Cuplock systems helps site managers, contractors, and procurement teams maximize safety, performance, and operational efficiency.

Strength and Load-Bearing Capacity

The primary advantage of Cuplock scaffolding lies in its ability to bear significant loads without compromising structural integrity. Key points include:

-

Vertical Load Support: Standards are engineered to carry heavy vertical loads from personnel, equipment, and materials.

-

Horizontal Stability: Ledgers and transoms distribute loads evenly, preventing bending or displacement.

-

Cup-and-Wedge Mechanism: Each connection ensures secure engagement, maintaining scaffold stability even under dynamic conditions.

-

Consistent Performance: High-grade steel construction prevents deformation over repeated assembly cycles.

-

Enhanced Safety Margins: Certified to EN and EU standards, ensuring compliance and reduced risk of structural failure.

Corrosion Resistance and Durability

European construction projects demand scaffolding that withstands environmental exposure. Cuplock systems feature:

-

Galvanized or Stainless Steel Components: Protect against rust, moisture, and industrial environments.

-

Long Service Life: Durable materials reduce maintenance frequency and extend scaffolding usability.

-

Wear-Resistant Connections: Cup-and-wedge locking points are precision-engineered to prevent loosening over time.

-

Sustained Performance: Resistant to UV exposure, chemical contact, and temperature fluctuations common in European sites.

Modular Design and Flexibility

Cuplock scaffolding offers unparalleled modularity, enabling rapid assembly and adaptation to complex structures. Features include:

-

Interchangeable Components: Standards, ledgers, and transoms can be combined to create customized layouts.

-

Adjustable Heights: Vertical standards allow multi-level scaffolding configurations.

-

Compatibility with Accessories: Guardrails, base plates, and braces integrate seamlessly into the system.

-

Rapid Reconfiguration: Supports dynamic project requirements, including temporary platforms and cantilevered structures.

-

Scalable Solutions: Modular elements allow expansion or reduction of scaffold size without compromising safety.

Integration with Other Scaffolding Systems

Cuplock systems can complement existing scaffolding frameworks, enhancing operational versatility. Integration features include:

-

Compatibility with Tube-and-Coupler Systems: Enables hybrid scaffolding setups for specialized project needs.

-

Support for Composite Platforms: Works with various board types and materials.

-

Cross-Bracing Connections: Maintain lateral stability when integrated with other scaffolding modules.

-

Seamless Component Replacement: Standardized fittings allow easy substitution of worn or damaged parts.

-

Enhanced Load Distribution: Maintains structural balance when combined with complementary scaffolding systems.

Key Features in Bullet Format

-

Cup-and-wedge locking system for secure and fast connections.

-

High load-bearing capacity certified to EN 74 and EN 12811 standards.

-

Galvanized or stainless steel construction for corrosion resistance.

-

Modular, interchangeable components allow flexible scaffolding design.

-

Rapid assembly and disassembly to reduce labor time.

-

Compatibility with guardrails, braces, and base plates for complete safety.

-

Durable under repeated use, maintaining mechanical integrity.

-

Adjustable vertical standards for multi-level scaffold configurations.

-

Integration with other scaffolding types for hybrid solutions.

-

Precise engineering for long-term stability and consistent performance.

Operational Advantages of Features

-

Reduced assembly and dismantling times, increasing project efficiency.

-

Lower maintenance costs due to durable, corrosion-resistant materials.

-

Enhanced worker confidence with standardized, reliable connections.

-

Scalable scaffolding solutions tailored to diverse project requirements.

-

Improved compliance with European safety standards for legal and operational security.

Applications in Construction Projects

Cuplock Standard Europe scaffolding systems are highly versatile and suitable for a wide range of construction environments across Europe. Their modular design, standardized components, and superior load-bearing capacity make them ideal for projects of varying scale and complexity. Construction managers, scaffolding contractors, and site engineers rely on Cuplock systems for safe, efficient, and adaptable scaffolding solutions.

Commercial Construction

In commercial construction, projects often involve multi-story buildings, large facades, and complex structural requirements. Cuplock scaffolding provides the flexibility and strength needed for these applications:

-

Supports multi-level platforms for workers and equipment.

-

Ensures structural stability for facades, cladding, and installation works.

-

Reduces installation time for tight project schedules.

-

Provides secure access for inspection, maintenance, and finishing tasks.

-

Integrates with temporary walkways, guardrails, and load-bearing accessories.

Industrial Construction

Industrial projects often involve heavy machinery, elevated structures, and extensive load requirements. Cuplock systems are well-suited to these challenges:

-

Handles higher loads due to reinforced standards and ledgers.

-

Supports large-scale equipment and material handling at height.

-

Facilitates scaffolding around complex machinery or irregular structures.

-

Modular design allows easy adaptation for varying platform heights and spans.

-

Compatible with protective barriers, braces, and safety accessories for worker protection.

Residential Construction

Residential sites require adaptability and efficiency, especially for limited-space environments and quick-turnaround projects. Cuplock scaffolding offers:

-

Lightweight yet durable components suitable for tight access areas.

-

Adjustable heights for multi-story homes or extensions.

-

Rapid assembly and disassembly to minimize disruption to the site.

-

Secure platforms for safe installation of windows, facades, and roofing.

-

Scalable solutions for small or large residential projects.

Specialized Construction Applications

Cuplock systems are also applicable in complex or temporary structures, including renovation, refurbishment, and temporary access platforms:

-

Easily accommodates cantilevered scaffolds, bridging, or suspended platforms.

-

Provides stability in irregular or uneven terrains.

-

Supports temporary pedestrian or material access ways safely.

-

Integrates with safety guardrails, toe boards, and braces for added protection.

-

Allows hybrid setups with other scaffolding systems for specialized project requirements.

Advantages of Cuplock in Construction Applications

-

Time Efficiency: Rapid assembly and dismantling reduce labor hours and project delays.

-

Load Distribution: Cup-and-wedge connections evenly distribute weight across standards and ledgers.

-

Safety Assurance: Compliance with EN 74 and EN 12811 ensures operational safety.

-

Modularity: Components can be reconfigured to change project requirements.

-

Durability: Corrosion-resistant materials maintain performance across multiple projects.

-

Accessibility: Provides secure platforms for personnel, tools, and materials.

-

Flexibility: Supports complex designs, including multi-level and cantilevered scaffolds.

-

Integration: Compatible with other scaffolding systems for hybrid structures.

-

Inspection Ease: Standardized components simplify regular maintenance and safety checks.

-

Scalability: Easily expandable for larger or evolving construction projects.

Operational Considerations

Construction teams benefit from Cuplock scaffolding by reducing assembly complexity while maintaining safety. The standardized components, precise engineering, and modular design streamline workflow and support adherence to European regulations. Procurement teams can also optimize inventory management due to component interchangeability and long service life, reducing overall project costs.

Benefits of Using Cuplock Standard

Cuplock Standard Europe scaffolding systems offer multiple operational, safety, and efficiency advantages for construction projects across Europe. Their modular design, standardized components, and compliance with EN and EU regulations make them a preferred solution for contractors, site managers, and procurement professionals seeking reliable scaffolding that meets diverse project requirements.

Enhanced Safety

Safety is paramount on construction sites, and Cuplock scaffolding is engineered to provide secure working platforms:

-

Secure Connections: Cup-and-wedge locking mechanisms ensure standards and ledgers remain tightly fastened.

-

Load-Bearing Reliability: High-strength materials distribute loads evenly, preventing structural failure.

-

Fall Protection: Integration with guardrails, toe boards, and braces reduces the risk of falls.

-

Compliance: EN 74 and EN 12811 certifications confirm adherence to European safety standards.

-

Structural Stability: Modular design prevents movement or swaying under dynamic site conditions.

Operational Efficiency

Cuplock systems are designed to save time and reduce labor requirements:

-

Rapid Assembly and Disassembly: Components can be connected quickly with minimal tools.

-

Modular Components: Standardized parts allow flexible adjustments without dismantling entire scaffolds.

-

Ease of Transport: Lightweight yet strong materials simplify handling and storage.

-

Reduced Downtime: Minimal adjustment requirements mean scaffolds remain operational throughout projects.

-

Simplified Inspection: Standardized layouts make safety checks quicker and more accurate.

Flexibility and Adaptability

Construction projects often require scaffolding that adapts to changing conditions. Cuplock scaffolding supports flexibility:

-

Multi-Level Platforms: Vertical standards accommodate varying heights across projects.

-

Cantilevered Applications: Supports extended platforms for complex structural requirements.

-

Compatibility with Other Systems: Can be integrated with tube-and-coupler or frame scaffolding.

-

Custom Configurations: Modular components allow layouts tailored to site constraints.

-

Reconfigurable Solutions: Easy modification to meet evolving project demands without additional components.

Durability and Long-Term Value

Investing in Cuplock scaffolding ensures long-term reliability:

-

Corrosion Resistance: Galvanized or stainless steel components withstand moisture, chemicals, and temperature variations.

-

Repetitive Use: Engineered for repeated assembly and disassembly without weakening joints.

-

Minimal Maintenance: High-quality materials reduce wear and inspection frequency.

-

Extended Lifecycle: Durable components provide consistent performance over multiple projects.

-

Cost Efficiency: Lower replacement and maintenance costs compared with non-standard scaffolding systems.

Environmental and Regulatory Compliance

European construction projects increasingly prioritize sustainability and adherence to regulations:

-

Certified Materials: Components meet EN and EU material and safety standards.

-

Reduced Waste: Long-lasting materials reduce the need for replacements.

-

Sustainable Manufacturing: Suppliers adhere to eco-friendly production methods.

-

Compliance Assurance: Documentation supports regulatory audits and site inspections.

-

Safer Work Practices: Standardized systems facilitate safer, more predictable workflows.

Installation Guidelines and Best Practices

Proper installation and maintenance are critical for ensuring that Cuplock Standard Europe scaffolding systems perform reliably and safely. For construction companies, scaffolding contractors, site managers, and procurement professionals, adherence to installation best practices maximizes operational efficiency, supports compliance with European standards, and enhances worker safety across commercial, industrial, and residential projects.

Preparation Before Installation

Before assembling a Cuplock scaffold, careful preparation ensures that the system functions as intended:

-

Site Assessment: Evaluate ground conditions for stability, level surfaces, and potential hazards.

-

Component Inspection: Check standards, ledgers, transoms, and cuplock nodes for damage, corrosion, or deformation.

-

Tools and Accessories: Ensure all required tools, base plates, braces, guardrails, and platforms are available and in good condition.

-

Planning Layout: Identify scaffold height, length, and platform configuration to determine the number and placement of components.

-

Compliance Verification: Confirm all components meet EN 74 and EN 12811 standards for European construction sites.

Step-by-Step Installation Process

-

Base Plate Placement: Position base plates on stable, level surfaces to support vertical standards.

-

Erecting Standards: Insert vertical standards into base plates, ensuring alignment and verticality.

-

Attaching Ledgers: Connect horizontal ledgers to standards using the cup-and-wedge locking mechanism.

-

Adding Transoms: Install transoms at specified intervals to support scaffold boards.

-

Securing Platforms: Place scaffold boards on transoms, ensuring proper engagement and alignment.

-

Integrating Safety Components: Install guardrails, toe boards, and diagonal braces for stability and fall protection.

-

Final Inspection: Verify all connections, alignment, and load distribution before allowing personnel on the scaffold.

Maintenance and Inspection Guidelines

Regular maintenance is essential to preserve the integrity and safety of Cuplock scaffolding:

-

Daily Inspections: Check for loose connections, worn components, or signs of corrosion before use.

-

Periodic Maintenance: Lubricate cup-and-wedge mechanisms if necessary, clean debris, and replace damaged parts.

-

Environmental Considerations: Inspect scaffolds after exposure to rain, high winds, or other adverse weather conditions.

-

Record-Keeping: Maintain documentation of inspections, maintenance, and repairs for compliance verification.

-

Component Replacement: Replace any compromised standards, ledgers, or transoms immediately to maintain safety standards.

Troubleshooting Common Issues

-

Loose Connections: Re-tighten cup-and-wedge locks and check for wear or deformation.

-

Misaligned Platforms: Adjust transoms or standards to ensure scaffold boards are level and secure.

-

Corrosion or Rust: Replace affected components and consider protective coatings for future use.

-

Uneven Load Distribution: Verify proper spacing of standards and transoms to balance loads effectively.

-

Component Damage: Remove and replace bent or cracked standards, ledgers, or transoms to maintain structural integrity.

Best Practices for Efficiency and Safety

-

Train all personnel in proper installation, inspection, and dismantling procedures.

-

Standardize component inventory to ensure compatibility and simplify assembly.

-

Follow manufacturer and regulatory guidelines for maximum load and height limitations.

-

Perform final verification before scaffold usage, including checking connections and guardrail placement.

-

Schedule regular maintenance and inspections to extend component lifespan and ensure safety.

Operational Advantages

-

Reduces installation time and labor costs through standardized components.

-

Enhances worker confidence with secure, compliant scaffolding platforms.

-

Minimizes risk of accidents or scaffold failure through proper assembly and maintenance.

-

Facilitates adaptability for complex layouts or site-specific conditions.

-

Supports regulatory compliance with EN and EU standards, reducing legal and operational risks.

Market Trends in Europe

The European construction industry continues to evolve, with increasing emphasis on safety, efficiency, and sustainable practices. Cuplock Standard Europe scaffolding systems play a significant role in this transformation, offering modular, durable, and compliant solutions for contractors, site managers, and procurement professionals. Understanding current market trends helps stakeholders anticipate demand, adopt innovations, and make informed decisions when sourcing scaffolding systems.

Rising Demand Across Construction Sectors

Cuplock scaffolding has become increasingly popular in Europe due to urbanization, infrastructure expansion, and heightened safety awareness. Key drivers of demand include:

-

Rapid development of commercial buildings, industrial facilities, and residential complexes.

-

Regulatory mandates emphasizing scaffold safety and compliance with EN 74 and EN 12811 standards.

-

Increased adoption of modular scaffolding solutions for efficient assembly and disassembly.

-

Growth in renovation, retrofit, and temporary scaffolding applications.

-

Preference for certified components from reliable Cuplock Standard Supplier Europe providers.

Technological Advancements

Modern Cuplock systems benefit from technological innovations that enhance performance, durability, and ease of use:

-

Precision-engineered cup-and-wedge connections for secure and reliable joints.

-

High-strength, corrosion-resistant materials that withstand environmental and operational stresses.

-

Lightweight designs for easier handling and reduced labor requirements.

-

Standardized components that facilitate hybrid setups with other scaffolding types.

-

Advanced quality control measures ensure consistent manufacturing and compliance verification.

Sustainability and Eco-Friendly Practices

Environmental considerations are increasingly influencing European construction choices. Cuplock suppliers are responding with eco-conscious designs and production methods:

-

Use of recyclable steel and durable materials to minimize waste.

-

Long-lasting components reduce the need for frequent replacements.

-

Adoption of environmentally responsible galvanization and coating processes.

-

Transparency in production practices to reduce carbon footprint and support sustainability goals.

-

Integration of sustainable scaffolding solutions within broader green building initiatives.

Integration with Digital Construction Practices

Digital tools and project management systems are shaping how scaffolding is planned, installed, and maintained:

-

Digital inventory tracking of Cuplock components for efficient supply chain management.

-

Integration with Building Information Modeling (BIM) to ensure compliance and precise placement.

-

Real-time monitoring of scaffold stability and component wear in large-scale projects.

-

QR code tagging of components for easy verification of certification and inspection history.

-

Data-driven maintenance schedules to optimize the lifespan and performance of scaffolding systems.

Regional Market Trends

Demand for Cuplock scaffolding varies across Europe based on project types and regulatory enforcement:

-

High adoption in Western Europe due to strict safety regulations and large commercial projects.

-

Growing utilization in Eastern Europe with expanding infrastructure and urbanization.

-

Consistent demand in residential construction across urban and suburban areas.

-

Industrial projects are driving the need for heavy-duty, multi-level scaffolding systems.

-

Temporary and modular scaffolding solutions are gaining traction for specialized applications.

Future Outlook

The European market for Cuplock systems is expected to expand as construction activity increases, safety awareness rises, and technological innovations continue. Key projections include:

-

Greater adoption of lightweight, high-strength materials for easier handling and transport.

-

Expansion of eco-friendly and recyclable scaffolding components across projects.

-

Integration with digital project management systems for real-time monitoring and compliance.

-

Wider use of Cuplock scaffolding in emerging European markets and infrastructure projects.

-

Continuous evolution of regulatory standards emphasizing safety, durability, and operational efficiency.

Operational Advantages for Stakeholders

-

Improved project planning with reliable, standardized scaffolding components.

-

Faster assembly and disassembly translate into time and cost savings.

-

Reduced risk of structural failures and enhanced worker safety.

-

Long-term value through durable, reusable components and lower replacement costs.

-

Support for sustainable construction practices aligned with European regulations.

Why Choose Affix Scaffolding?

Selecting a trusted supplier for Cuplock Standard Europe scaffolding is critical for construction companies, scaffolding contractors, site managers, and procurement officers. Affix Scaffolding stands out as a reliable Cuplock Standard Supplier Europe, offering high-quality components, expert guidance, and exceptional service across European markets. Our commitment to quality, safety, and efficiency ensures that scaffolding systems meet rigorous regulatory requirements while supporting smooth, cost-effective operations.

Reliable Product Quality

Affix Scaffolding prioritizes the integrity and performance of every Cuplock component. Key aspects of our product quality include:

-

Certified Materials: Standards, ledgers, transoms, and accessories are manufactured from galvanised or stainless steel to ensure durability.

-

Load-Bearing Strength: Each component is engineered to meet EN 74 and EN 12811 specifications for vertical and horizontal loads.

-

Precision Engineering: Cup-and-wedge mechanisms are designed for secure, repeatable connections.

-

Corrosion Resistance: Components withstand moisture, chemical exposure, and environmental fluctuations.

-

Consistent Performance: High-quality manufacturing ensures components maintain structural integrity through multiple assembly cycles.

Technical Expertise and Support

Beyond supplying scaffolding components, Affix Scaffolding provides specialized technical assistance:

-

Guidance on selecting components suited to project specifications and site conditions.

-

Step-by-step installation instructions for safe and efficient assembly.

-

Regular maintenance recommendations and troubleshooting advice.

-

Verification of compliance with European safety standards.

-

Assistance with inventory management and logistical planning for large projects.

Commitment to Safety and Compliance

Worker safety is central to our philosophy. By sourcing certified Cuplock Standard Europe systems from Affix Scaffolding, construction professionals ensure compliance and risk mitigation:

-

All products undergo rigorous quality control before shipment.

-

Components are certified to meet EN and EU regulatory standards.

-

Documentation and certificates support audits and inspections.

-

Systems are designed to maintain stability under operational and environmental loads.

-

Technical support ensures correct installation and ongoing maintenance for continued safety.

Customer-Centric Approach

Affix Scaffolding delivers tailored solutions and responsive service to meet diverse project requirements:

-

Flexible supply options for small-scale and large-scale construction projects.

-

Personalized consultations to address site-specific requirements and complex scaffolding configurations.

-

Efficient order processing and timely delivery throughout Europe.

-

Transparent communication regarding specifications, compliance, and component certification.

-

Post-purchase support for maintenance, replacement, and operational guidance.

Sustainability and Environmental Responsibility

We recognize the growing importance of sustainable construction practices in Europe. Affix Scaffolding integrates eco-conscious strategies into operations:

-

Durable, recyclable materials that reduce long-term waste.

-

Eco-friendly galvanization and coating processes to minimize environmental impact.

-

Long-lasting scaffolding systems reduce the need for frequent replacements.

-

Supplier practices are aligned with European environmental regulations.

-

Promoting efficient scaffolding solutions that support sustainable construction practices.

Key Advantages of Choosing Affix Scaffolding

-

Trusted Cuplock Standard Supplier Europe with extensive market experience.

-

Certified, high-quality components compliant with EN 74 and EN 12811 standards.

-

Durable, corrosion-resistant materials for long-term performance.

-

Modular components enabling flexible, scalable scaffolding solutions.

-

Expert technical support for installation, maintenance, and troubleshooting.

-

Tailored service with responsive consultation and project support.

-

Commitment to safety, ensuring secure scaffolding systems for all construction sites.

-

Sustainable and eco-conscious products and production processes.

-

Reliable delivery and supply across European markets.

-

Assurance of regulatory compliance and operational efficiency.

Contact Details

For inquiries, consultations, or orders, Affix Scaffolding can be reached at:

-

Email: info@affixscaffolding.eu

-

Phone: 00 358 40 060 6046

FAQs – Cuplock Standard Europe

1. What makes Cuplock scaffolding different from other systems?

Cuplock scaffolding uses a unique cup-and-wedge locking mechanism for secure, rapid connections between standards, ledgers, and transoms. Unlike traditional tube-and-coupler scaffolding, it allows modular assembly, superior load distribution, and compliance with European safety standards, making it suitable for commercial, industrial, and residential construction projects.

2. How do I choose the right Cuplock components for my project?

Selection depends on scaffold height, load requirements, platform configuration, and environmental exposure. Ensure all components comply with EN 74 and EN 12811 standards. Consider corrosion resistance, material quality, and supplier certification. Choosing components correctly maximizes safety, operational efficiency, and long-term reliability.

3. Can Cuplock scaffolding be used in complex or irregular structures?

Yes, Cuplock’s modular design allows adaptation to multi-level, cantilevered, or irregularly shaped structures. Its standardized components facilitate hybrid configurations with other scaffolding types, maintaining stability, compliance with European standards, and operational flexibility across diverse construction applications.

4. What materials are Cuplock components typically made from?

High-strength galvanized or stainless steel is commonly used. These materials offer corrosion resistance, durability, and load-bearing capacity. Quality materials ensure long-term performance, reduce maintenance, and maintain compliance with EN 74 and EN 12811 for European construction projects.

5. How often should Cuplock scaffolding be inspected?

Components should be inspected before installation, regularly during use, and after exposure to adverse weather. Key checks include secure connections, wear, deformation, or corrosion. Consistent inspections ensure platform stability, safety, and ongoing compliance with European safety regulations.

6. Are Cuplock scaffolds suitable for outdoor environments?

Yes. European-standard Cuplock scaffolds are designed to withstand outdoor conditions. Corrosion-resistant materials and protective coatings maintain structural integrity in rain, humidity, or temperature fluctuations. Properly installed and maintained scaffolds remain safe and durable across all construction sites.

7. What are the safety advantages of using Cuplock scaffolding?

Safety benefits include secure cup-and-wedge connections, stable load distribution, compatibility with guardrails and braces, EN-certified components, and reduced risk of displacement or collapse. Cuplock systems provide reliable platforms, enhancing worker safety and compliance with European construction regulations.

8. Do suppliers provide support for installation and maintenance?

Reputable Cuplock Standard Supplier Europe companies, such as Affix Scaffolding, offer technical guidance for installation, maintenance, and troubleshooting. They provide documentation, compliance verification, and step-by-step instructions to ensure safe use, extend component life, and maintain scaffolding performance.

9. How do I ensure Cuplock scaffolding meets European standards?

Verify EN 74 and EN 12811 certification from the supplier. Check component load ratings, material specifications, and test records. Using certified Cuplock Standard Europe products guarantees compliance with EU safety regulations, enhances worker safety, and provides legal assurance for construction projects.

10. What factors influence the longevity of Cuplock scaffolding?

Key factors include material quality, proper installation, regular maintenance, environmental exposure, and correct load management. Using certified Cuplock Standard Europe components, performing inspections, and addressing wear or damage promptly ensures long-term performance, platform stability, and safe construction operations.

Specifications

Cuplock Standard

|