Products

-

Adjustable Base Jack

-

Adjustable U Head Jack

-

Adjustable Universal Jack

-

Aluminium Beam-Double Web Heavy

-

Aluminium Beam-Single Web Heavy

-

Aluminium Beam-Single Web Light

-

Aluminium Lattice beam

-

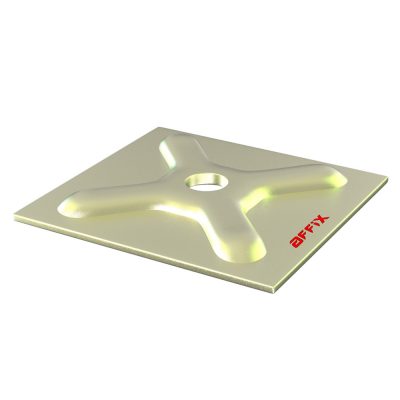

Base Plate

-

Beam Bracket

-

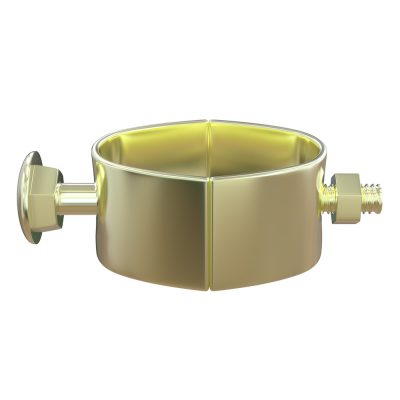

Board Retaining Coupler

-

Cantilever Frame

-

Castor Wheels

-

Cuplock Intermediate Transom

-

Cuplock Ledger

-

Cuplock Spigot Pin

-

Cuplock Standard

-

Cuplock Swivel Face Braces

-

Double Cantilever Frame

-

Double Coupler

-

Fork U-Head Jack

-

Galvanized Pipe

-

Girder Coupler

-

H Frames

-

H20 Beams

-

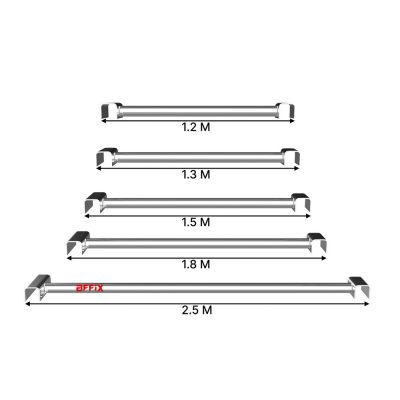

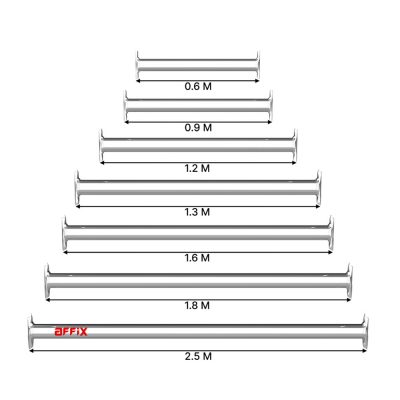

Ladder Beam

-

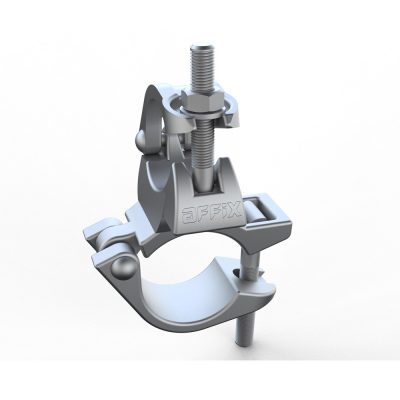

Ladder Clamp

-

Pressed Sleeve Coupler

-

Prop Jacks

-

Push Pull Prop

-

Single Coupler

-

Staircase Unit

-

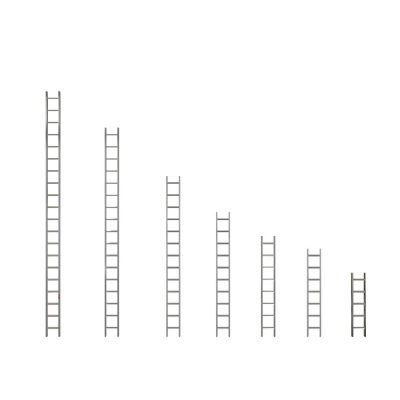

Steel Ladder

-

Steel Planks

-

Swivel Adjustable Base Jack

-

Swivel Coupler

-

Tie Rods

-

Toe Board Clamp

-

Universal Clamps

-

Waller Plate

-

Water Barrier Nut

-

Wing Nut

-

Wooden Planks

Applications

Cuplock System Scaffolding for Sale Europe

Cuplock system scaffolding is a versatile modular scaffolding solution widely used across Europe for construction, maintenance, and industrial projects. Its distinctive design features pre-engineered cup-shaped nodes that allow for quick and secure connections between ledgers and standards. This system provides robust structural stability, supports complex configurations, and significantly reduces assembly time compared to traditional scaffolding. Cuplock scaffolding accommodates various building heights and shapes, ensuring safe, efficient, and reliable access for workers. Its strength, durability, and adaptability make it an ideal choice for European contractors and facility managers seeking efficient scaffolding solutions for diverse project requirements.

Why Cuplock Scaffolding Is Popular in Europe?

Cuplock scaffolding has become a preferred choice for contractors, facility managers, and industrial professionals across Europe due to its combination of efficiency, strength, and adaptability. The system’s modular design and pre-engineered connections provide advantages that traditional scaffolding cannot match, making it ideal for residential, commercial, and industrial projects. European construction trends emphasize speed, safety, and compliance, and Cuplock scaffolding aligns seamlessly with these requirements.

Modular and Efficient Construction

The modular nature of Cuplock scaffolding allows rapid assembly and dismantling without specialized tools. Pre-engineered cup connections ensure that ledgers and standards fit securely, reducing the risk of errors during setup. This modularity allows for flexible configurations to accommodate:

-

High-rise building construction.

-

Renovation and maintenance of complex structures.

-

Temporary platforms for industrial inspections and installations.

-

Multi-level scaffolding for varied architectural designs.

The efficiency of modular Cuplock scaffolding minimizes labor requirements, speeds up project timelines, and reduces overall costs, making it a highly practical solution for European construction sites.

Safety and Stability

Safety is a primary consideration in European construction, and Cuplock scaffolding delivers exceptional stability through its innovative locking mechanism. Each cup connector securely holds horizontal and diagonal members in place, preventing slippage or movement under load.

Key safety features include:

-

Secure cup connections that resist accidental detachment.

-

Robust steel standards capable of supporting heavy loads.

-

Compatibility with guardrails and anti-slip platforms for worker protection.

-

Stable foundations suitable for uneven or challenging terrains.

The design ensures compliance with European safety regulations, providing contractors and facility managers with confidence that workers are operating on a secure platform.

Versatility Across Project Types

Cuplock scaffolding is suitable for a wide range of project types across Europe:

-

Residential Projects: Access for painting, facade work, and home renovations.

-

Commercial Projects: Scaffolding for offices, retail complexes, and multi-story buildings.

-

Industrial Facilities: Platforms for equipment maintenance, inspections, and retrofitting.

-

Infrastructure Projects: Scaffolding for bridges, tunnels, and municipal structures.

Its adaptability allows for straight, curved, and irregular configurations, enabling safe access to areas where traditional scaffolding may be impractical.

European Trends Favoring Cuplock

European construction emphasizes modular systems that reduce assembly time and improve efficiency. Cuplock scaffolding meets these demands by:

-

Offering lightweight yet strong steel components with corrosion-resistant coatings.

-

Allowing rapid repositioning of scaffolds on multi-site projects.

-

Reducing the need for specialized labor due to intuitive assembly.

-

Complying with EN scaffolding standards to meet regulatory expectations.

These characteristics support the increasing demand for flexible, safe, and reliable scaffolding solutions across European construction and industrial projects.

Key Features of Affix Cuplock Scaffolding

Affix Cuplock scaffolding combines innovation, strength, and versatility to meet the rigorous demands of European construction, industrial, and maintenance projects. Designed with precision-engineered components, this system ensures rapid assembly, secure connections, and long-term durability. Its features provide contractors, facility managers, and industrial professionals with reliable scaffolding solutions that enhance safety, efficiency, and adaptability across diverse applications.

Pre-Engineered Connection System

One of the defining features of Cuplock scaffolding is its unique pre-engineered cup and wedge connection system. Each standard has multiple cups positioned at fixed intervals, allowing horizontal ledgers and diagonal braces to be locked into place securely.

Advantages of this system:

-

Simplifies assembly, reducing setup time significantly.

-

Ensures uniform alignment and precise geometry for safe scaffolding structures.

-

Minimizes the need for specialized tools or complex training.

-

Reduces errors during construction, enhancing overall site safety.

The pre-engineered design allows workers to assemble scaffolding quickly while maintaining consistent strength and stability throughout the structure.

High-Strength Steel Components

Affix Cuplock scaffolding utilizes premium-grade steel standards and ledgers. Each component is engineered to withstand heavy loads while maintaining rigidity and structural integrity.

Steel component benefits:

-

High tensile strength for superior load-bearing capacity.

-

Resistance to bending or deformation under extreme weight.

-

Supports multi-level scaffolding arrangements safely.

-

Provides long-term durability for repeated use across multiple projects.

The combination of high-strength steel and precision manufacturing ensures the scaffolding can handle rigorous operational demands without compromising safety.

Corrosion-Resistant Coating

All Affix Cuplock scaffolding components are treated with advanced anti-corrosion coatings. This protective layer enhances longevity, particularly for outdoor projects exposed to weather and moisture.

Benefits of corrosion-resistant coating:

-

Prolongs service life in damp or outdoor environments.

-

Reduces maintenance costs and the need for replacement parts.

-

Maintains structural integrity even under harsh conditions.

-

Ensures reliable performance in coastal, industrial, and chemical-prone areas.

This feature is particularly important for European projects where scaffolding may be exposed to varying climatic conditions.

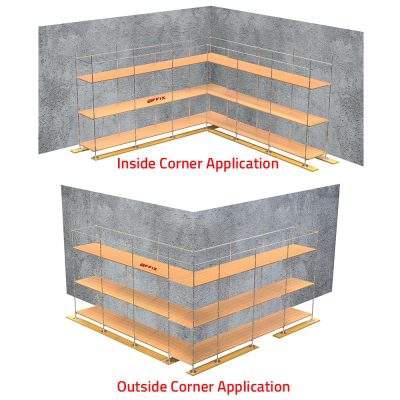

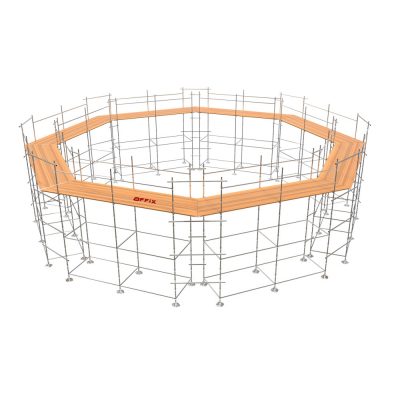

Versatile Configuration

Affix Cuplock scaffolding is designed for flexible and modular configurations. Components can be assembled in straight, curved, or complex arrangements to match architectural or industrial requirements.

Configuration advantages include:

-

Adaptable to different building heights and layouts.

-

Supports multi-level access platforms and staircases.

-

Compatible with custom modular assemblies for unique project demands.

-

Enables efficient use of space and materials on-site.

The versatility of Cuplock scaffolding allows contractors to address diverse project challenges with a single, modular system.

High Load-Bearing Capacity and Durability

Cuplock scaffolding is engineered to support heavy loads while maintaining safety and stability. Each standard and ledger is designed to distribute weight evenly across the structure.

Key durability and load features:

-

Multi-point cup connections enhance load distribution.

-

Suitable for both personnel and equipment on multiple levels.

-

Durable steel and protective coatings resist wear and fatigue.

-

Ensures long-term usability for repetitive projects across Europe.

Reliable load-bearing capacity reduces the risk of accidents and contributes to safer, more efficient project execution.

Benefits of Using Cuplock Scaffolding

Affix Cuplock scaffolding offers European contractors, facility managers, and industrial professionals a combination of safety, efficiency, and versatility that traditional scaffolding systems cannot match. Its modular design, pre-engineered connections, and durable construction provide tangible advantages across construction, industrial maintenance, and infrastructure projects. Choosing Cuplock scaffolding enhances project timelines, reduces labor costs, and ensures worker safety, making it a reliable solution for diverse European applications.

Quick Installation and Dismantling

One of the primary benefits of Cuplock scaffolding is the speed and simplicity of assembly. The pre-engineered cup connections allow components to be joined without specialized tools, significantly reducing setup and dismantling time.

Advantages include:

-

Reduced labor costs and fewer personnel required for assembly.

-

Rapid deployment across multiple project sites.

-

Easy reconfiguration for changing project requirements.

-

Minimal downtime between stages of construction or maintenance.

The ability to quickly assemble and dismantle scaffolding accelerates project schedules, particularly for tight timelines or multi-site operations.

Enhanced Safety

Cuplock scaffolding provides secure and stable elevated access, reducing the risk of accidents on site. The cup-and-wedge connection system ensures that all ledgers and braces are firmly locked in place, while guardrails and anti-slip platforms enhance worker protection.

Safety benefits include:

-

Stable connections resistant to accidental dislodging.

-

Strong load-bearing capacity for personnel and equipment.

-

Compatibility with EN-compliant guardrails and safety platforms.

-

Reduced risk of scaffolding collapse or structural failure.

By providing a secure working platform, Cuplock scaffolding contributes to a safer environment for contractors and industrial staff across European projects.

Flexible Design for Various Heights and Structures

Cuplock scaffolding accommodates diverse architectural and industrial requirements. Its modular design allows structures to be adapted for different heights, widths, and building shapes, supporting both simple and complex projects.

Flexibility benefits include:

-

Ability to create straight, curved, or custom configurations.

-

Integration of staircases, access platforms, and multi-level arrangements.

-

Adaptation for residential, commercial, industrial, and infrastructure projects.

-

Efficient use of space and material on-site.

This flexibility ensures that scaffolding can be tailored to meet project-specific needs without compromising safety or performance.

Long Service Life and Low Maintenance

Affix Cuplock scaffolding is constructed from high-strength steel with corrosion-resistant coatings, ensuring long-term durability. Its robust materials and modular components require minimal maintenance, reducing operational costs and enhancing return on investment.

Durability advantages include:

-

Resistance to bending, deformation, and wear over repeated use.

-

Protection against corrosion in outdoor and industrial environments.

-

Minimal component replacement, reducing downtime and costs.

-

Long-term reliability for multiple projects across Europe.

The extended service life of Cuplock scaffolding makes it a cost-effective choice for contractors managing ongoing construction or industrial operations.

Types of Cuplock Scaffolding Available

Affix offers a comprehensive range of Cuplock scaffolding solutions to meet the diverse needs of European contractors, facility managers, and industrial professionals. The system’s modular design allows for a variety of configurations suitable for construction, maintenance, industrial, and infrastructure projects. Different types of Cuplock scaffolding provide flexibility, accessibility, and safety for both simple and complex structures.

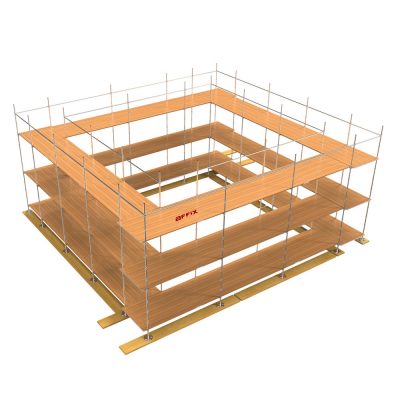

Standard Cuplock Frames and Ledger Systems

Standard Cuplock scaffolding frames and ledgers form the core of any modular structure. The pre-engineered cup-and-wedge connections allow rapid assembly while maintaining structural stability.

Applications of standard frames:

-

Creating multi-level scaffolding for residential, commercial, and industrial projects.

-

Forming straight or curved scaffold runs for various building designs.

-

Supporting work platforms, guardrails, and temporary access structures.

-

Providing the foundational framework for customized assemblies.

Key advantages:

-

Quick installation due to intuitive design.

-

High load-bearing capacity for personnel and equipment.

-

Modular construction enables expansion or reduction of scaffold dimensions.

-

Durability and corrosion resistance for long-term usage.

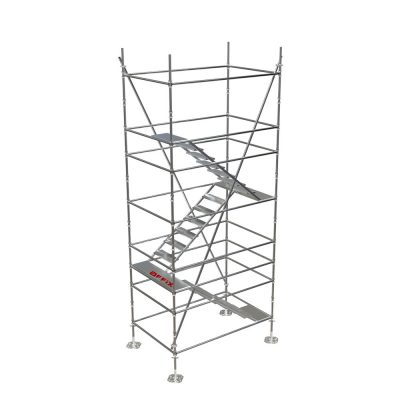

Staircases and Access Platforms

Safety and accessibility are critical in scaffolding design. Affix offers Cuplock staircases and access platforms to provide secure movement between levels.

Applications of staircases and platforms:

-

Safe vertical access for construction personnel and industrial workers.

-

Integration into multi-level scaffolding structures for efficient workflow.

-

Support for temporary maintenance, inspection, or renovation tasks.

-

Customizable platform heights for project-specific requirements.

Benefits include:

-

Enhanced worker safety with stable steps and anti-slip surfaces.

-

Easy integration with standard frames and ledgers.

-

Modular design allows reconfiguration or relocation as needed.

-

Compliance with European safety regulations for access and fall protection.

Custom Modular Assemblies

For projects with unique architectural or industrial requirements, Affix provides custom modular Cuplock scaffolding assemblies. These are tailored to meet specific height, width, and load requirements while maintaining safety and compliance.

Applications of custom assemblies:

-

Complex industrial structures require irregular scaffolding shapes.

-

Renovation projects involving historic or irregular building facades.

-

Infrastructure projects such as bridges, tunnels, or municipal facilities.

-

Industrial maintenance in chemical, petrochemical, or power plant environments.

Key advantages:

-

Configurable components to fit unconventional structures.

-

Maintain all safety features, including secure cup connections and load-bearing capacity.

-

Reduce material waste by using components efficiently.

-

Adaptable to changing project requirements without compromising safety.

Compliance with European Safety Standards

Affix Cuplock scaffolding is engineered to meet the stringent safety and quality standards required across Europe. Compliance with European regulations ensures that scaffolding systems provide reliable, safe, and durable access for construction, industrial, and maintenance projects. By adhering to EN 12810 and EN 12811 standards, Affix guarantees that its Cuplock scaffolding meets performance requirements for load-bearing capacity, stability, and worker safety.

EN 12810 and EN 12811 Standards

EN 12810 specifies the design and performance criteria for facade scaffolding made of prefabricated elements, covering aspects such as structural strength, dimensional tolerances, and materials.

EN 12811 focuses on performance requirements for access and working scaffolds, ensuring safety, stability, and adequate load-bearing capacity.

By meeting these standards, Affix Cuplock scaffolding ensures that all components, including frames, ledgers, braces, and platforms, are designed and tested to withstand the operational demands of European construction and industrial sites.

Rigorous Testing and Certification

Affix subjects all Cuplock scaffolding components to strict quality control and testing procedures. Each element is verified for:

-

Load-bearing capacity under various conditions.

-

Structural stability when assembled in multiple configurations.

-

Resistance to environmental factors, including corrosion and wear.

-

Precise dimensions for seamless modular assembly.

Certification processes confirm that every batch of scaffolding components adheres to EN standards, ensuring safety and compliance on-site.

Safe Assembly and Usage Guidelines

Compliance extends beyond materials and design to include clear assembly and usage protocols. Affix guides to ensure scaffolding is installed correctly, maintaining:

-

Proper alignment of cup connections and ledgers.

-

Stable foundation with base plates or adjustable jacks.

-

Secure installation of guardrails, toe boards, and platforms.

-

Regular inspection routines to verify structural integrity.

These practices minimize risks and ensure the scaffolding performs as intended, even under heavy loads or complex configurations.

Benefits of Compliance

Using EN-compliant Cuplock scaffolding offers multiple advantages for European projects:

-

Legal adherence: Ensures scaffolding meets European construction and occupational safety regulations.

-

Reduced liability: Enhances worker safety, minimizing the potential for accidents and associated claims.

-

Reliability: Verified structural performance under heavy loads and extended use.

-

Project efficiency: Faster approval for site deployment due to certified compliance.

-

Adaptability: Modular components conform to required safety standards across diverse project types.

Industries & Applications Across Europe

Affix Cuplock scaffolding serves a broad range of industries and applications across Europe, providing safe, efficient, and adaptable access solutions for construction, maintenance, and industrial projects. Its modular design, high load-bearing capacity, and versatile configurations make it suitable for various sectors, from residential buildings to complex industrial facilities. European contractors, facility managers, and project teams rely on Cuplock scaffolding to meet safety standards while ensuring operational efficiency.

Construction and Civil Engineering

In construction and civil engineering projects, Cuplock scaffolding is widely used to provide elevated platforms, working areas, and safe access for personnel and equipment.

Applications include:

-

Multi-story building construction.

-

Renovation and refurbishment of residential and commercial structures.

-

Bridge and tunnel projects require stable, temporary platforms.

-

Facade work, painting, and exterior maintenance.

Benefits for construction use:

-

Modular system allows adaptation to varying building heights and layouts.

-

Pre-engineered cup connections reduce assembly time, improving project efficiency.

-

High-strength steel ensures stability for personnel and materials.

-

EN-compliant components maintain safety standards for European construction sites.

Industrial Facilities and Maintenance Projects

Industrial facilities such as manufacturing plants, warehouses, and power stations require scaffolding for maintenance, inspections, and equipment installation. Cuplock scaffolding provides safe, reliable, and adaptable access in these environments.

Applications include:

-

Maintenance of heavy machinery and production lines.

-

Installation of electrical or mechanical systems.

-

Inspection of structural components and industrial equipment.

-

Access to storage racks and elevated platforms.

Industrial benefits:

-

Flexible configurations accommodate complex industrial layouts.

-

High load-bearing capacity supports equipment and multiple workers.

-

Durable steel construction resists wear in high-traffic industrial settings.

-

Rapid assembly and dismantling reduce downtime for maintenance projects.

Oil, Gas, and Power Plants

Specialized projects in oil, gas, and power generation facilities often require scaffolding that is strong, durable, and safe under challenging conditions. Cuplock scaffolding is suitable for these sectors due to its structural integrity and EN compliance.

Applications include:

-

Access for refinery and pipeline maintenance.

-

Installation of turbines, generators, or other heavy equipment.

-

Temporary platforms for inspections and repairs.

-

Safe access to confined or elevated work areas.

Benefits for energy sector use:

-

Pre-engineered connections enhance safety and stability.

-

Corrosion-resistant coatings protect against harsh industrial environments.

-

Modular design adapts to complex infrastructure layouts.

-

High load capacity ensures safe handling of personnel and tools.

Large-Scale Infrastructure and Renovation Projects

Cuplock scaffolding is ideal for large-scale infrastructure and renovation projects across Europe, where safety, flexibility, and efficiency are paramount.

Applications include:

-

Bridge, highway, and tunnel construction or refurbishment.

-

Urban infrastructure maintenance projects.

-

Historic building restoration requiring customized scaffolding shapes.

-

Temporary platforms for inspection and civil engineering operations.

Advantages in infrastructure projects:

-

Versatility for straight, curved, or irregular structures.

-

Modular components allow scaling for large or complex projects.

-

Secure cup connections provide stability in multi-level scaffolds.

-

Durable, corrosion-resistant steel ensures long-term reliability.

Why Choose Affix for Cuplock Scaffolding in Europe?

Affix is a trusted supplier and manufacturer of Cuplock scaffolding across Europe, providing high-quality, reliable, and compliant scaffolding systems for contractors, industrial professionals, and facility managers. The combination of advanced engineering, strict quality control, and customer-focused services makes Affix an ideal partner for European projects of any scale or complexity.

Trusted Manufacturer and Supplier

Affix has established itself as a reputable supplier of Cuplock scaffolding systems in Europe. Every component is manufactured with precision and undergoes rigorous quality control to ensure durability, stability, and compliance with European standards.

Key advantages:

-

Consistent product quality through stringent manufacturing processes.

-

EN-compliant scaffolding components meeting European safety requirements.

-

Reliable supply for projects ranging from small-scale renovations to large infrastructure developments.

-

Seamless integration with existing scaffolding systems or new modular assemblies.

Contractors and facility managers can rely on Affix for consistent quality and dependable delivery, ensuring smooth project execution.

High-Quality Materials with Long Service Life

Affix Cuplock scaffolding is constructed from premium-grade steel, treated with corrosion-resistant coatings to provide long-lasting performance. Components are designed to withstand heavy loads, harsh environments, and repeated use without compromising safety or structural integrity.

Material benefits include:

-

High tensile steel for superior strength and load capacity.

-

Corrosion-resistant finishes for outdoor and industrial applications.

-

Durable design for multi-year use across multiple projects.

-

Reduced maintenance and replacement costs due to long service life.

These materials ensure that Affix Cuplock scaffolding remains a cost-effective solution for long-term European projects.

Competitive Pricing and Bulk Supply

Affix offers competitive pricing for Cuplock scaffolding without compromising quality, making it accessible for contractors and industrial professionals managing tight budgets. Additionally, bulk supply options allow for large-scale projects to be executed efficiently.

Advantages of Affix pricing and supply:

-

Cost-effective solutions for both small and large projects.

-

Bulk availability ensures seamless project scheduling and reduced downtime.

-

Flexible purchasing options tailored to project requirements.

-

Reduced logistics costs with reliable European distribution channels.

Contractors benefit from predictable costs and uninterrupted access to high-quality scaffolding materials.

Fast Delivery Across Europe

Affix maintains an extensive distribution network to provide rapid delivery across European countries. This ensures that projects can proceed without delays caused by material shortages.

Delivery benefits include:

-

Timely supply to multiple construction or industrial sites.

-

Efficient logistics minimize transportation and handling time.

-

Flexible shipping options for urgent or scheduled deliveries.

-

Reliable support for project managers and procurement teams.

Fast and dependable delivery ensures that scaffolding is available when needed, keeping projects on schedule.

Customer Support and Technical Assistance

Affix provides responsive customer service to assist with product selection, technical questions, and on-site support. This level of service ensures that contractors and facility managers can maximize the efficiency and safety of their scaffolding systems.

Support advantages:

-

Expert advice on scaffolding configuration and selection.

-

Guidance on compliance with European safety standards.

-

Technical assistance for assembly, maintenance, and inspection.

-

Dedicated support for bulk orders and large-scale project planning.

By combining high-quality products with knowledgeable customer support, Affix helps clients achieve successful project outcomes.

Contact Information

For inquiries, quotations, or technical assistance regarding Cuplock scaffolding in Europe, contact Affix:

-

Email: info@affixscaffolding.eu

-

Phone: 00 358 40 060 6046

FAQs

1. What is Cuplock scaffolding and how is it different from traditional scaffolding?

Cuplock scaffolding features a modular system with pre-engineered cup-and-wedge connections, allowing rapid assembly and strong, stable structures. Unlike traditional tube-and-clamp scaffolding, Cuplock provides higher load capacity, modular flexibility, and enhanced safety for construction, industrial, and infrastructure projects across Europe.

2. Are Affix Cuplock scaffolding components compliant with European safety standards?

Yes, all Affix Cuplock scaffolding components meet EN 12810 and EN 12811 standards. These certifications ensure structural integrity, load-bearing capacity, and safe use in construction, industrial, and maintenance projects throughout Europe, providing compliance with regional occupational safety regulations.

3. Can Cuplock scaffolding be customized for complex structures?

Affix offers modular and custom configurations for Cuplock scaffolding. Components can be adapted to varying heights, widths, and building shapes, supporting multi-level access, staircases, and platforms. This flexibility ensures safe and efficient scaffolding for unique European construction and industrial projects.

4. What materials are used in Affix Cuplock scaffolding?

Affix Cuplock scaffolding is constructed from high-strength steel treated with corrosion-resistant coatings. This combination ensures durability, long service life, and resistance to harsh outdoor or industrial environments, making it suitable for repeated use across diverse European projects.

5. How quickly can Cuplock scaffolding be assembled and dismantled?

The pre-engineered cup connections and modular design allow rapid assembly and dismantling. Projects benefit from reduced labor costs, minimal downtime, and flexibility to relocate or reconfigure scaffolding as needed, enhancing efficiency on European construction and industrial sites.

6. Is Cuplock scaffolding suitable for heavy industrial applications?

Yes, Cuplock scaffolding supports multi-level access with high load-bearing capacity, making it ideal for industrial facilities, oil and gas plants, power stations, and manufacturing sites. Its robust design ensures stability and safety when handling personnel and equipment simultaneously.

7. Can Cuplock scaffolding be used for renovation and restoration projects?

Absolutely. The modular and flexible design allows scaffolding to conform to historic or irregular building facades, bridges, tunnels, and other renovation projects. Components can be configured to provide safe access without compromising structural integrity or worker safety.

8. How does Affix ensure the quality and reliability of scaffolding products?

Affix employs rigorous quality control, including material testing, dimensional verification, and load capacity checks. Each component undergoes certification to meet European standards, ensuring reliable performance, safety, and long-term durability for construction and industrial applications.

9. Are there additional components available for enhanced safety and versatility?

Yes. Affix provides guardrails, toe boards, platforms, staircases, diagonal braces, base plates, and adjustable jacks. These components integrate seamlessly with Cuplock scaffolding, improving worker safety, structural stability, and adaptability for various European project requirements.

10. How can I purchase Affix Cuplock scaffolding in Europe?

Contractors and industrial professionals can contact Affix via email or phone to request quotations, bulk orders, or technical assistance. Affix offers fast delivery, competitive pricing, and responsive support across Europe, ensuring projects receive safe, reliable, and compliant scaffolding solutions.