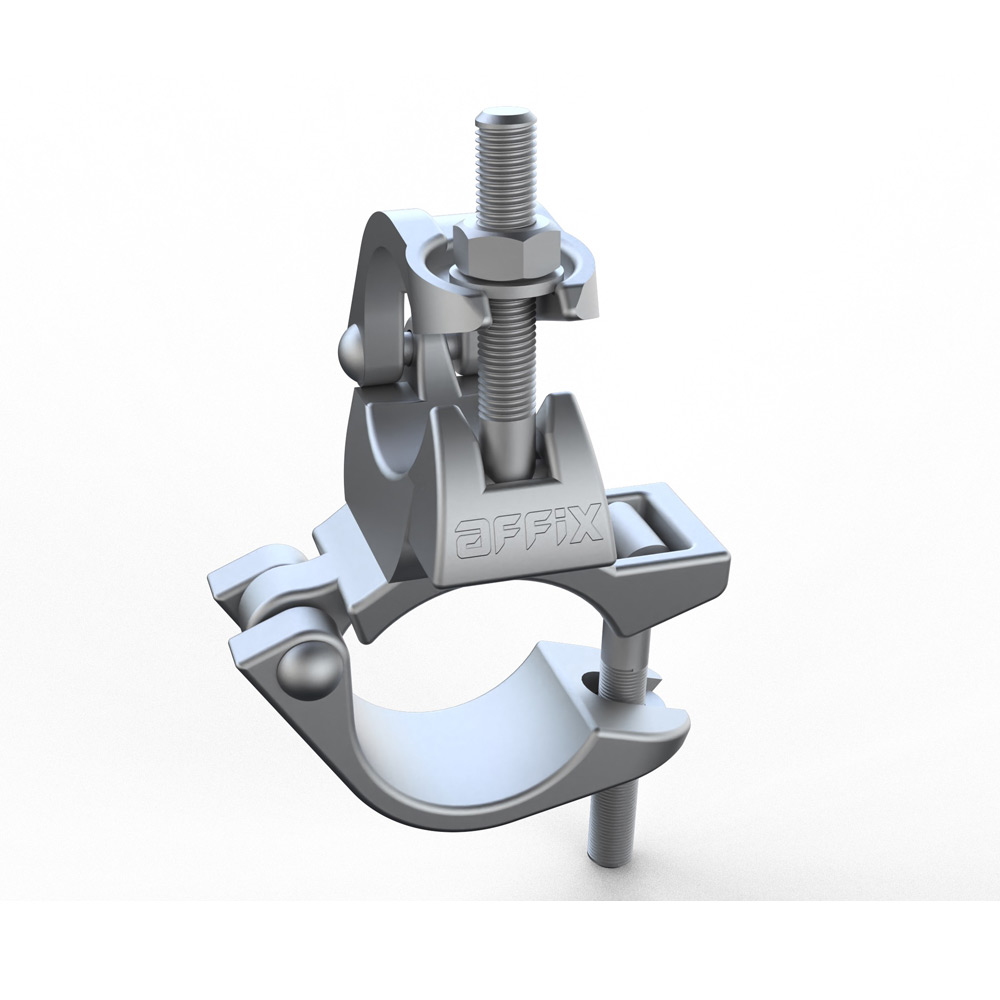

Double Coupler

Model No. FCF08

A fixed ninety-degree, rigid coupler by Affix, used for connecting two 48.3mm tubes at right angles. This heavy duty fitting is designed for use in all types of scaffolding construction and also in lighting rigs, staging and guard rails. All the drop forged scaffold fittings are zinc plated for longer life, manufactured to BS 1139 (Part 2) & EN 74 and are tested to ensure the highest level of quality control. Our drop forged doubles are Class B. This fitting is also available as a pressed steel fitting.

|

Scaffolding systems are the backbone of safe and efficient construction projects, and couplers are the key components that ensure structural integrity. Among them, the double coupler for sale in Europe is one of the most widely used fittings, essential for creating strong, stable scaffolding connections. With the rising demand in European infrastructure, industrial maintenance, and construction projects, the need for high-quality couplers has never been greater. As a leading double coupler supplier in Europe, Affix Scaffolding provides durable, safety-compliant solutions tailored for diverse applications. Our premium range ensures reliability, safety, and compliance for scaffolding buyers across Europe.

What is a Double Coupler?

A scaffolding system is only as strong as the connections that hold it together. The double coupler Europe plays a vital role in ensuring the stability, safety, and durability of scaffold structures used in construction and industrial projects. It is one of the most essential fittings used across building sites, maintenance projects, and infrastructure development throughout Europe.

Definition and Purpose

A double coupler, sometimes referred to as a right-angle coupler, is a scaffolding fitting designed to connect two tubes at 90 degrees. Its function is simple yet critical: it locks horizontal and vertical scaffold tubes securely, creating the rigid framework required for load-bearing scaffolding systems. Without double couplers, scaffold structures would lack the rigidity needed to support workers, materials, and equipment at height.

Key Features of Double Couplers

Some essential features that define the importance of a double coupler for sale in Europe include:

-

Right-Angle Connection: Provides a secure 90-degree joint between two scaffold tubes.

-

Strong Grip: Designed to resist slippage, ensuring that tubes remain firmly locked in place.

-

Durable Material: Typically manufactured from forged or pressed steel for long-lasting performance.

-

Corrosion Protection: Available with galvanized or coated finishes to withstand harsh environments.

-

Standardized Design: Built to comply with European safety standards, including EN 74.

Role in Scaffolding Structures

Double couplers are indispensable in creating the main framework of scaffolding systems. Their applications include:

-

Building Scaffolds: Connecting standards (vertical tubes) to ledgers (horizontal tubes).

-

Supporting Platforms: Providing stability to working decks and platforms.

-

Industrial Access: Ensuring secure frameworks in factories, plants, and maintenance areas.

-

Infrastructure Projects: Supporting large-scale bridge, road, and tunnel construction scaffolds.

By providing secure joints, double couplers make scaffolding systems more robust and capable of handling heavy-duty work across different sectors.

Applications Across Industries

The demand for double couplers in Europe is not limited to one sector. These fittings are widely used in:

-

Construction Industry: Essential for safe access and support structures during building works.

-

Maintenance Projects: Used in factories, warehouses, and industrial facilities for repair and upkeep tasks.

-

Energy Sector: Supporting scaffolds in oil, gas, and renewable energy projects.

-

Public Infrastructure: Applied in roadworks, rail projects, and urban development scaffolding.

Their versatility makes them a staple for any scaffolding setup, no matter the scale or complexity.

Importance of Compliance

In Europe, construction safety standards are stringent, and double couplers must meet recognized regulations. The most common compliance is EN 74, which specifies performance requirements for couplers. Choosing couplers that meet these standards ensures not only legal compliance but also safety for workers and protection for contractors against liabilities.

Advantages of Using Double Couplers

The double coupler for sale in Europe is one of the most widely trusted scaffolding fittings, and its popularity is rooted in the many advantages it offers to contractors, construction companies, and industrial users. These fittings are not only simple in design but also deliver exceptional strength, stability, and versatility, making them indispensable in European scaffolding systems.

Strong Grip and Secure Connections

One of the primary reasons contractors rely on the double coupler in Europe is its ability to provide a strong grip on scaffold tubes. Once tightened, the coupler firmly locks two tubes at right angles, preventing slippage or loosening even under heavy loads. This secure connection is crucial in scaffolding, where worker safety and structural stability depend on the integrity of every joint.

-

Provides rigid 90-degree tube connections.

-

Prevents tube movement or shifting during use.

-

Withstands vibration, wind, and external forces.

Enhanced Stability and Safety

Safety is always the top priority in construction and industrial environments. Double couplers contribute significantly to scaffold stability by ensuring that standards and ledgers remain firmly joined. By forming the backbone of scaffold structures, they help distribute weight evenly and minimize risks of collapse or imbalance.

-

Promotes safe working platforms.

-

Ensures scaffolding remains stable under pressure.

-

Reduces hazards associated with weak or loose fittings.

Durability and Heavy Load Resistance

Manufactured from high-grade forged or pressed steel, double couplers are designed to handle demanding conditions. Their robust construction allows them to support significant weight without bending or breaking. In heavy-duty construction projects, durability is non-negotiable, and the double coupler supplier European market provides fittings that meet these needs consistently.

-

Resistant to bending or breaking under heavy loads.

-

Long service life due to tough steel construction.

-

Reliable performance even in challenging environments.

Corrosion Protection for Longevity

Many scaffolding projects in Europe are exposed to outdoor elements, making corrosion resistance a vital feature. Galvanized or coated double couplers offer excellent protection against rust, ensuring that they remain effective and safe even after prolonged use in harsh weather conditions.

-

Galvanized finish enhances rust resistance.

-

Suitable for long-term outdoor applications.

-

Reduces maintenance costs by extending lifespan.

Versatility Across Scaffolding Structures

Another key advantage of the double coupler for sale in Europe is its versatility. It can be used in a wide range of scaffolding structures, from small residential setups to large-scale industrial frameworks. This adaptability makes it an ideal choice for contractors and suppliers who serve different types of projects.

-

Suitable for residential, commercial, and industrial scaffolds.

-

Compatible with standard tube sizes used across Europe.

-

Can be integrated into temporary or long-term structures.

Compliance with Safety Standards

European regulations require scaffolding components to meet strict safety standards. Double couplers are manufactured to comply with EN 74, ensuring they are tested for load capacity, grip strength, and durability. Contractors who choose compliant couplers benefit from peace of mind, knowing their scaffolds are legally and structurally sound.

-

Certified to meet EN 74 standards.

-

Provides confidence in meeting safety requirements.

-

Reduces liability for contractors and companies.

Market Demand for Double Couplers in Europe

The demand for the double coupler for sale in Europe continues to grow, reflecting the rapid development of the construction and infrastructure industries across the continent. As safety requirements become stricter and projects expand in scale, the need for reliable, durable, and certified scaffolding components such as double couplers has significantly increased.

Expansion of Construction and Infrastructure Projects

European cities are undergoing extensive growth, with new infrastructure, residential complexes, commercial towers, and industrial facilities constantly being built. Double couplers play a critical role in ensuring these projects are completed safely and efficiently. Their ability to secure tubes at right angles makes them vital for building stable scaffolding frameworks.

-

Used in housing and urban development projects.

-

Essential for constructing high-rise buildings and bridges.

-

Supports the expansion of transportation infrastructure across Europe.

Industrial and Energy Sector Growth

The industrial and energy sectors, including oil refineries, power plants, and shipyards, rely heavily on scaffolding systems. In these demanding environments, double coupler Europe fittings are indispensable for creating strong, stable access platforms. With many European nations investing in renewable energy, double couplers are increasingly required for safe access to turbines and industrial machinery.

-

Critical for scaffolding in the oil and gas industries.

-

Widely used in power generation projects.

-

Supports heavy-duty scaffolds in shipbuilding and industrial plants.

Growing Safety Regulations Across Europe

European Union regulations mandate that scaffolding components meet strict safety standards, including EN 74 compliance. Contractors and construction companies are therefore prioritizing high-quality, certified couplers over cheaper, non-compliant alternatives. This shift has resulted in rising demand for reputable double coupler suppliers in Europe who can deliver certified products that pass rigorous safety checks.

-

EN 74 compliance drives purchasing decisions.

-

Buyers demand verified load-bearing and grip strength.

-

Focus on minimizing workplace risks and legal liabilities.

Shift Toward Standardization

Construction projects across Europe increasingly demand standardized scaffolding components to ensure compatibility, efficiency, and safety. The double coupler for sale European market aligns with this trend by offering fittings that match common tube sizes, enabling contractors to work with interchangeable, reliable parts across different sites.

-

Standard sizes improve project efficiency.

-

Compatibility reduces downtime in assembly.

-

Easier to maintain scaffolding inventories across projects.

Trends in Purchasing vs. Rental Markets

Scaffolding equipment can either be purchased outright or rented for short-term projects. While rental remains common for temporary works, more contractors are opting to buy durable double couplers for long-term use. The longevity and reusability of forged or galvanized couplers make ownership a cost-effective choice, especially for companies managing multiple projects.

-

Rentals are popular for short-duration jobs.

-

Purchases favored for continuous, long-term projects.

-

Ownership reduces dependency on third-party suppliers.

Demand Across Diverse Sectors

The appeal of double coupler Europe fittings spans multiple industries due to their adaptability. They are used not only in traditional construction but also in event staging, industrial maintenance, and even restoration of heritage buildings. This wide application range makes double couplers a constant requirement for suppliers across Europe.

-

Construction of commercial and residential buildings.

-

Maintenance scaffolds for factories and plants.

-

Scaffolding for cultural and historical restoration.

-

Temporary structures for events and exhibitions.

Key Drivers of Market Growth

The upward trend in demand can be attributed to several factors that consistently reinforce the importance of high-quality couplers:

-

Expansion of infrastructure and industrial development projects.

-

Increasing enforcement of safety regulations.

-

Standardization across European scaffolding systems.

-

Cost-effectiveness of durable, reusable couplers.

-

Rising adoption of scaffolding in non-construction sectors.

Technical Specifications

When investing in scaffolding components, technical details matter as much as durability and safety. The double coupler for sale in Europe is engineered to meet stringent standards, ensuring it delivers the strength and reliability required on construction and industrial sites. Contractors, site engineers, and procurement teams across Europe rely on precise specifications to guarantee compatibility and compliance.

Standard Sizes and Tube Compatibility

Double couplers are manufactured to fit the standard scaffolding tube diameters used across Europe. These sizes allow them to connect horizontal ledgers to vertical standards securely at a 90-degree angle. Their compatibility ensures seamless integration into existing scaffolding systems.

-

Compatible with 48.3 mm diameter scaffold tubes.

-

Designed to maintain precise right-angle connections.

-

Interchangeable with standard European scaffolding fittings.

Material Construction

Durability starts with material quality. The double coupler Europe market offers fittings made from forged or pressed steel, each providing distinct advantages. Forged steel couplers are valued for their exceptional strength, while pressed steel versions are lighter yet still strong enough for medium-duty projects.

-

Drop-forged steel for maximum load resistance.

-

Pressed steel options for lighter scaffolding setups.

-

Galvanized coating to resist corrosion and rust.

Weight Capacity and Load Resistance

Load-bearing ability is a critical factor in choosing double couplers. They are engineered to handle substantial weight while keeping scaffolding structures stable. High-quality couplers are tested to support demanding construction environments, providing confidence to contractors and site managers.

-

Withstands dynamic and static loads effectively.

-

Tested for heavy-duty scaffolding applications.

-

Ensures safe working platforms under pressure.

Corrosion Protection and Finishes

European construction often involves outdoor projects where weather exposure is unavoidable. Galvanized double couplers are treated with a protective zinc coating, enhancing resistance against rust and extending service life. This makes them suitable for both short-term and long-term projects.

-

Hot-dip galvanized finish for maximum corrosion resistance.

-

Protects against rain, humidity, and harsh environments.

-

Reduces frequency of replacement and maintenance costs.

Safety Standards and Compliance

Every double coupler supplier in Europe must ensure that their fittings comply with strict European regulations. EN 74 certification is the industry benchmark, proving that the couplers meet performance standards for grip strength, load resistance, and material durability. Using certified couplers helps contractors comply with legal and workplace safety requirements.

-

Manufactured to EN 74 standards.

-

Tested for strength and durability.

-

Approved for use in European construction projects.

Locking Systems and Stability Features

Double couplers are equipped with strong bolt-and-nut locking systems that guarantee secure fastening of scaffold tubes. This locking mechanism is designed to withstand vibrations, heavy winds, and constant use on active worksites.

-

High-tensile bolts for reliable tightening.

-

Nuts are designed for repeated tightening and loosening.

-

Maintains rigid, immovable connections.

Why Choose Affix Scaffolding for Double Couplers in Europe?

Selecting the right supplier is as important as selecting the right product. In the case of scaffolding, where safety and reliability are paramount, partnering with a trusted source is critical. Affix Scaffolding has established itself as a dependable choice for contractors and construction companies seeking double couplers for sale in Europe. With a commitment to quality, compliance, and customer satisfaction, our company delivers more than just products—we deliver confidence and long-term value.

Leading Double Coupler Supplier in Europe

Affix Scaffolding is recognized as a reliable double coupler supplier in Europe, offering a wide range of scaffolding fittings tailored for various industries. Our focus is on providing components that meet the highest standards of safety and durability, ensuring every connection contributes to the overall integrity of scaffolding systems.

-

Known for consistent quality across product ranges.

-

Supply network covering multiple European countries.

-

Long-standing partnerships with contractors and businesses.

Wide Product Range

Every project has unique demands, and Affix Scaffolding ensures that buyers can find the right solution without compromise. From forged steel couplers for heavy-duty use to pressed steel versions for lighter applications, our portfolio includes options that match different load requirements, budgets, and environments.

-

Drop-forged couplers for maximum strength.

-

Pressed steel couplers for medium-duty needs.

-

Galvanized options are designed for corrosion resistance.

Commitment to European Standards

Safety and compliance are non-negotiable. All our double couplers are manufactured in accordance with EN 74 standards, ensuring they meet the stringent requirements for load capacity, grip strength, and material reliability. By choosing Affix Scaffolding, buyers can be confident they are sourcing products aligned with European safety laws.

-

Products are tested for strength and durability.

-

Certified compliance with EN 74 standards.

-

Trusted by contractors across regulated sectors.

Competitive Pricing and Bulk Order Options

We understand that cost efficiency is essential for contractors managing multiple projects. Affix Scaffolding provides competitive pricing structures, making it easier for businesses to purchase high-quality double couplers without exceeding budget limits. For larger projects, bulk order benefits help reduce overall procurement costs.

-

Affordable pricing without compromising quality.

-

Discounts available for bulk purchases.

-

Flexible supply solutions for ongoing projects.

Europe-Wide Delivery

Timely supply is crucial in construction. Affix Scaffolding ensures quick and efficient delivery across Europe, helping contractors avoid project delays. With a streamlined logistics system, we provide reliable access to double couplers for sale in Europe, no matter where your project is located.

-

Fast delivery to construction hubs across Europe.

-

Efficient handling of both small and large orders.

-

Reliable supply chain to minimize downtime.

After-Sales Support

Our responsibility doesn’t end at delivery. Affix Scaffolding provides after-sales support to assist buyers with technical queries, product details, or additional requirements. This ongoing partnership ensures contractors feel supported throughout their projects.

-

Dedicated customer support for queries.

-

Guidance on technical specifications.

-

Continued assistance for long-term clients.

Why Contractors Choose Affix Scaffolding?

The growing number of clients selecting Affix Scaffolding for double coupler Europe is not a coincidence. Our reputation is built on consistency, trust, and the ability to deliver fittings that perform reliably under demanding conditions. Contractors value our ability to balance cost, quality, and service in every order.

Buying Guide – How to Choose the Right Double Coupler

Choosing the correct scaffolding components is critical for ensuring worker safety, project efficiency, and compliance with European standards. Among these components, the double coupler for sale in Europe is a cornerstone of stability in scaffolding structures. However, not all couplers are the same, and selecting the wrong type can compromise safety, add unnecessary costs, or cause delays. This buying guide provides a comprehensive overview to help contractors, procurement teams, and construction managers make informed decisions when sourcing from a double coupler supplier in Europe.

Step 1: Understand the Role of Double Couplers

Before purchasing, it is essential to understand what a double coupler does. These fittings are specifically designed to connect scaffold tubes at a 90-degree angle, ensuring maximum rigidity and strength in the overall framework. They prevent unwanted movement and provide a stable foundation for work platforms.

-

Ensures secure tube-to-tube connection.

-

Prevents scaffolding structures from shifting.

-

Creates reliable load-bearing joints.

When evaluating double couplers in Europe, knowing their role will guide you toward selecting a coupler that suits your project requirements.

Step 2: Assess Material Quality

Not all couplers are manufactured with the same material standards. High-quality steel, often hot-dip galvanized or zinc-coated, is ideal for ensuring durability and resistance to corrosion. Inferior materials can weaken over time, leading to safety risks.

-

Forged steel couplers: Known for superior strength, ideal for heavy-duty projects.

-

Pressed steel couplers: Lighter but still strong, suitable for general applications.

-

Galvanized finish: Protects against rust, extending product lifespan.

Always source from a double coupler supplier in Europe that guarantees certified steel materials.

Step 3: Check Compliance with EN 74 Standards

European projects require couplers that meet EN 74 safety standards. This certification confirms that the coupler has been tested for load-bearing capacity, slip resistance, and durability. Choosing uncertified couplers may lead to legal issues, fines, or compromised worker safety.

-

Verify EN 74 compliance before purchase.

-

Request certification documents from the supplier.

-

Ensure batch testing and traceability for large orders.

Affix Scaffolding ensures every double coupler for sale in Europe meets these requirements.

Step 4: Consider Load Capacity

Different projects place varying demands on scaffolding systems. Understanding the load capacity of a double coupler ensures it can handle the weight safely. Heavy-duty industrial applications may require forged couplers, while lighter construction projects may work efficiently with pressed couplers.

-

Match coupler type with project weight requirements.

-

Avoid underestimating loads to prevent failures.

-

Consult with suppliers for recommendations.

Step 5: Evaluate Corrosion Resistance

Europe experiences diverse weather conditions, from humid coastal regions to snowy winters. Couplers with strong anti-corrosion coatings are critical for outdoor scaffolding. Zinc-plated or hot-dip galvanized finishes extend service life and reduce maintenance costs.

-

Choose couplers designed for long-term outdoor use.

-

Prioritize galvanized products for industrial environments.

-

Confirm protective coatings are uniform and tested.

Step 6: Compare Pricing and Value

While cost is always a consideration, the cheapest option is not always the most economical in the long run. Poor-quality couplers may require frequent replacement or cause costly safety incidents.

-

Balance price with quality.

-

Seek suppliers offering bulk discounts.

-

Calculate long-term savings from durable products.

Affix Scaffolding provides competitively priced double couplers in Europe without sacrificing quality.

Step 7: Look at Supplier Reliability

The best products lose value if they are not delivered on time. A trusted double coupler supplier in Europe ensures timely availability, consistent stock, and professional after-sales support.

-

Review the supplier's track record.

-

Assess delivery capabilities across Europe.

-

Check for customer testimonials and reputation.

Affix Scaffolding stands out for its dependable supply chain and customer service.

Step 8: Factor in Project-Specific Requirements

Not every project is the same. Some require couplers for long-term scaffolding, while others demand temporary but robust solutions. Considering these factors will help you avoid overbuying or underbuying.

-

Industrial projects: Heavy-duty forged couplers.

-

Residential construction: Pressed couplers may suffice.

-

Offshore/harsh environments: Prioritize corrosion resistance.

Applications of Double Couplers Across Industries

The double coupler for sale in Europe is one of the most versatile and essential scaffolding components used across multiple industries. Its ability to firmly connect tubes at right angles makes it indispensable in projects that demand strength, stability, and safety. Whether for small-scale works or large industrial operations, double couplers are critical in ensuring scaffolding frameworks remain reliable.

Residential and Housing Projects

In Europe’s housing sector, contractors rely heavily on double couplers to assemble safe scaffolding systems for new builds, renovations, and maintenance work. Home improvement projects, roof repairs, and external painting often demand lightweight yet durable scaffolding, where double couplers provide the required rigidity.

-

Supports temporary structures during roofing and exterior work.

-

Provides stability for safe worker platforms.

-

Ensures compliance with European safety standards in residential projects.

Commercial Construction

For office complexes, shopping centers, and large buildings, scaffolding systems need to handle higher loads and provide greater height. Double couplers serve as the backbone for these setups, creating secure joints that resist movement even under heavy stress.

-

Ideal for tall scaffolding structures.

-

Enhances worker safety in high-rise projects.

-

Provides reliable connections for demanding commercial applications.

Industrial and Infrastructure Projects

Heavy-duty infrastructure projects such as bridges, factories, and power plants require couplers that can endure extreme pressure and challenging environments. Forged couplers with galvanized finishes are particularly suitable, ensuring long-term resistance to wear and corrosion.

-

Used for high-load industrial scaffolding.

-

Performs reliably in harsh conditions like offshore sites.

-

Critical for long-term, heavy-duty scaffolding setups.

Event and Temporary Structures

Beyond traditional construction, the double coupler supplier in Europe serves industries such as events and exhibitions. Event organizers use scaffolding frameworks for staging, seating, and lighting setups, relying on double couplers for their strength and ease of assembly.

-

Supports temporary platforms and stages.

-

Provides stability for lighting rigs and seating stands.

-

Enables quick assembly and disassembly.

Shipbuilding and Marine Works

In shipyards and ports, scaffolding faces exposure to saltwater and extreme weather. Galvanized double couplers are preferred here due to their corrosion resistance, ensuring safe maintenance and construction of vessels.

-

Maintains stability for dockside scaffolding.

-

Withstands marine weather conditions.

-

Extends service life in high-moisture environments.

FAQs

1. What is the purpose of a double coupler in scaffolding?

A double coupler connects two scaffold tubes at right angles, forming secure joints that maintain structural stability. This fitting is vital for strength, load-bearing capacity, and safety compliance in scaffolding systems, ensuring reliable support for workers and materials in various construction and industrial projects.

2. Are double couplers suitable for heavy-duty scaffolding applications?

Yes, high-quality double coupler Europe fittings are engineered to handle demanding loads. Manufactured from forged steel and galvanized for durability, they offer exceptional resistance to pressure and stress, making them ideal for heavy-duty construction, infrastructure, and industrial projects requiring robust and secure scaffolding connections.

3. Do double couplers meet European safety standards?

All premium double coupler supplier Europe products from Affix Scaffolding comply with EN 74 standards, ensuring safety, quality, and consistency. Compliance with these regulations guarantees secure performance, giving contractors peace of mind that their scaffolding structures adhere to strict European requirements for safety and reliability.

4. What materials are double couplers made from?

Double couplers are typically produced using drop-forged or pressed steel, often with galvanized finishes. This ensures corrosion resistance, strength, and long-term reliability. These materials allow couplers to perform in diverse European environments, from large infrastructure projects to smaller construction sites, maintaining stability under challenging conditions.

5. Can double couplers be reused for multiple projects?

Yes, with proper maintenance and inspection, double coupler Europe products can be reused across numerous projects. Their robust steel construction ensures a long lifespan. However, regular checks for wear, rust, or damage are essential to guarantee ongoing safety and compliance with European scaffolding regulations.

6. What factors should contractors consider before purchasing double couplers?

Contractors should evaluate project requirements, load-bearing needs, compliance with EN 74 standards, and whether forged or pressed steel is more suitable. Durability, safety certifications, and supplier reliability also play a crucial role. Affix Scaffolding helps businesses select the right double coupler for sale in Europe.

7. How do double couplers differ from swivel couplers?

A double coupler is designed to fix tubes at right angles, ensuring rigid joints and structural stability. In contrast, swivel couplers allow tubes to connect at varying angles for more flexible designs. Both are essential, but double couplers provide unmatched rigidity in scaffolding frameworks.

8. What load capacity can be expected from quality double couplers?

The load capacity of double coupler Europe fittings varies by size, material, and design. Generally, forged steel versions deliver superior performance, capable of withstanding significant loads in construction. Specifications align with EN 74 standards, ensuring dependable strength for large-scale scaffolding projects across Europe.

9. Do double couplers come with corrosion protection?

Yes, many double coupler suppliers in Europe offer galvanized options for corrosion resistance. This protective coating extends the lifespan of the fitting, especially in outdoor or harsh environments. Choosing galvanized couplers ensures long-term durability, reduced maintenance needs, and reliable safety for all scaffolding applications.

10. How can I order double couplers from Affix Scaffolding?

Ordering is simple. Contact Affix Scaffolding directly via 00 358 40 060 6046 or info@affixscaffolding.eu. Our team provides expert advice, bulk pricing options, and fast delivery across Europe, ensuring you receive premium double coupler for sale Europe products tailored to your project requirements.