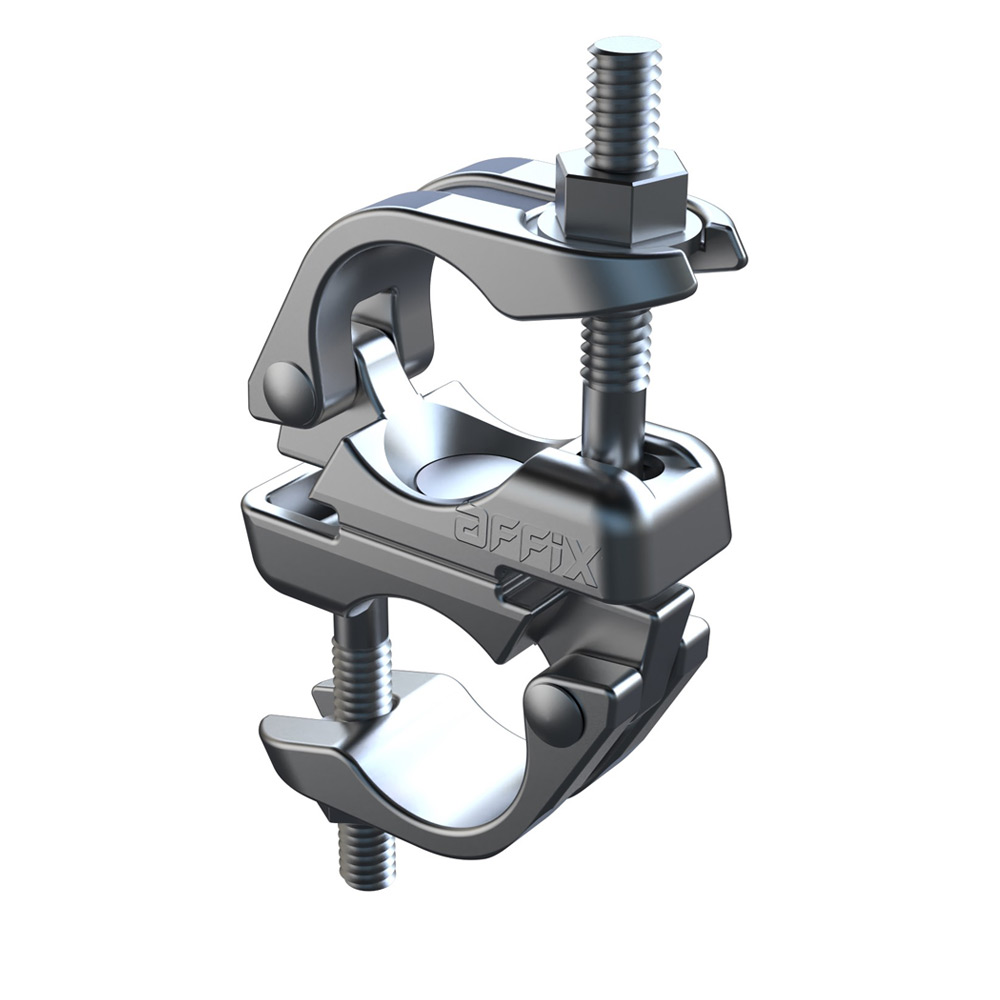

Swivel Coupler

Model No. FCF09

Forged swivel coupler by Affix, used for connecting two 48.3mm tubes at any angle. This fitting is designed for use in all types of scaffolding construction, most often employed where diagonal bracing is required and also in lighting rigs, staging and guard rails. All the forged scaffold fittings are zinc plated for longer life. Manufactured to BS 1139 (Part 2) & EN 74 and are tested to ensure the highest level of quality control.

This fitting is also available as a pressed steel fitting.

|

Swivel coupler for Sale in Europe

Scaffolding couplers are the foundation of safe, reliable, and adaptable scaffolding systems, ensuring tubes remain firmly secured under demanding conditions. Among these, the swivel coupler for sale in Europe stands out as an essential component, enabling flexible tube connections at varying angles for complex structures. With increasing construction, industrial, and infrastructure projects across Europe, the demand for high-quality swivel couplers in Europe continues to rise. As a trusted swivel coupler supplier in Europe, Affix Scaffolding delivers durable, safety-certified couplers designed to meet European standards, providing contractors and companies with secure, long-lasting solutions tailored to diverse project needs.

What is a Swivel Coupler?

A swivel coupler for sale in Europe is one of the most versatile fittings in scaffolding systems, widely used across residential, commercial, and industrial projects. Its primary function is to connect two scaffold tubes at any angle, providing the flexibility to construct complex scaffolding frameworks where standard right-angle joints may not suffice. This adaptability makes swivel couplers indispensable for structures requiring diagonal bracing, irregular layouts, or additional support in confined spaces.

At its core, a swivel coupler consists of two parts joined by a central swivel bolt, enabling movement and rotation. Unlike fixed couplers, which lock tubes at rigid angles, swivel couplers allow adjustment during assembly, providing greater design freedom while maintaining structural integrity. Their flexibility ensures contractors can adapt scaffold systems to the specific requirements of each project, whether for building facades, bridges, industrial maintenance, or shipyards.

Key Features of Swivel Couplers

-

Adjustable connections: Allowing tubes to connect at virtually any angle.

-

Forged or pressed steel construction: Ensuring strength and durability.

-

Galvanized finishes: Offering resistance against corrosion and harsh environmental conditions.

-

Load-bearing capacity: Supporting diagonal bracing and additional scaffold reinforcement.

-

Compliance: Designed to meet European EN 74 standards.

These features not only provide strength but also flexibility, making them suitable for challenging project conditions where precision and adaptability are essential.

Applications Across Industries

The swivel coupler is widely used in a variety of sectors, reflecting its importance:

-

Construction projects: Ideal for irregular structures and diagonal support.

-

Industrial maintenance: Used in factories, plants, and refineries where space and design may be restricted.

-

Infrastructure development: Bridges, tunnels, and roadworks benefit from the adjustable connections offered by swivel couplers.

-

Shipbuilding and ports: Providing adaptability for scaffolding around curved or irregular surfaces.

-

Restoration projects: Offering secure solutions for older buildings with non-standard architectural layouts.

Importance of Scaffolding Systems

Swivel couplers are not just connectors—they are critical to the strength and adaptability of the scaffolding system. By allowing tubes to be joined at multiple angles, they provide both stability and design flexibility. Contractors rely on these fittings to meet safety standards while completing complex tasks efficiently. Without swivel couplers, scaffolding systems would be limited to rigid frameworks, restricting their use in many advanced or irregular projects.

Benefits to Contractors and Companies

For contractors and companies working across Europe, swivel couplers deliver several essential benefits:

-

Enhanced flexibility for challenging or custom scaffolding layouts.

-

Time-saving assembly thanks to quick and secure connections.

-

Compliance assurance with EN 74 safety requirements.

-

Compatibility with standard scaffold tubes commonly used across Europe.

-

Long-term durability, even in demanding weather or industrial environments.

Swivel couplers are, therefore, not just practical but also an investment in safety and efficiency. By choosing high-quality products from a reliable swivel coupler supplier in Europe like Affix Scaffolding, buyers ensure their scaffolding systems remain safe, compliant, and adaptable to any project requirement.

Advantages of Using Swivel Couplers

The swivel coupler for sale in Europe has become a critical component in scaffolding systems because it combines flexibility, strength, and compliance. For contractors, builders, and industrial buyers, the advantages of these couplers extend beyond simple connections, offering practical benefits that directly impact project safety, efficiency, and cost management.

Unlike fixed couplers, swivel couplers provide adaptability, allowing tubes to be connected at almost any angle. This feature alone transforms scaffolding into a versatile solution capable of handling complex designs, irregular structures, and confined spaces. Yet, the advantages go far deeper.

1. Versatility in Construction Projects

One of the primary reasons swivel coupler Europe products are in high demand is their unmatched versatility. They enable scaffold tubes to be positioned diagonally or at non-standard angles, making them indispensable for:

-

Curved or irregular building facades.

-

Bridge and tunnel work requires angled supports.

-

Restoration of historic buildings with unconventional layouts.

-

Industrial facilities where space is restricted.

This adaptability ensures that no matter the project’s complexity, swivel couplers deliver the flexibility required to achieve a stable and secure scaffold.

2. Secure and Flexible Connections

Swivel couplers are engineered for strength as well as adaptability. Their ability to securely clamp tubes ensures scaffolding remains safe under pressure while still allowing contractors the freedom to adjust angles. Key benefits include:

-

Firm grip on scaffold tubes even under load.

-

Secure fastening mechanisms that reduce movement and risk of accidents.

-

Flexibility without compromising safety, essential for complex layouts.

By combining flexibility with strength, swivel couplers strike the perfect balance for modern scaffolding requirements.

3. Durability Under Heavy Loads

High-quality swivel couplers suppliers in Europe, such as those offered by Affix Scaffolding, are built from forged or pressed steel. Many are also galvanized to prevent rust and wear. This ensures:

-

High load-bearing capacity to support diagonal bracing.

-

Resistance to corrosion for long-term outdoor use.

-

Durability in demanding environments, including industrial and coastal areas.

Such features make swivel couplers a reliable investment that delivers performance across multiple projects without frequent replacements.

4. Compliance with Safety Standards

Safety is the cornerstone of every scaffolding system. Swivel couplers are manufactured to meet EN 74 European standards, guaranteeing their reliability. Advantages of compliance include:

-

Assurance that scaffolding meets EU safety regulations.

-

Reduced liability risks for contractors and companies.

-

Confidence that the equipment has undergone rigorous testing.

This compliance adds value for buyers who require dependable equipment that will not compromise worker safety.

5. Cost-Effectiveness for Contractors

Although swivel couplers are specialized fittings, they deliver long-term cost benefits by reducing project delays and minimizing the need for additional equipment. Their adaptability allows contractors to use fewer fittings while still achieving secure scaffolding designs.

Key points of cost-effectiveness:

-

Multi-project reusability due to durable materials.

-

Reduced need for specialized components, thanks to versatility.

-

Faster assembly, cutting labor hours on-site.

Market Demand for Swivel Couplers in Europe

The demand for swivel couplers for sale in Europe has seen steady growth as the European construction and industrial sectors expand. With urban development, large-scale infrastructure projects, and strict safety regulations driving demand, swivel couplers are increasingly viewed as essential scaffolding components. Their ability to connect tubes at various angles makes them vital for complex projects, and their reliability under heavy loads positions them as a preferred choice for contractors and companies across the continent.

Expansion of Construction and Infrastructure Projects

Europe is witnessing significant investment in new housing, commercial buildings, and large-scale infrastructure. This has created a continuous requirement for scaffolding systems capable of supporting diverse designs and layouts. The swivel coupler Europe has become a critical component for:

-

Residential developments require safe scaffolding for multi-story buildings.

-

Commercial complexes with unique architectural designs.

-

Infrastructure projects, including bridges, tunnels, and highways.

-

Renovation and restoration work, where adaptability is essential.

The ability to connect tubes at any angle ensures scaffolding systems can be customized to meet the needs of these varied projects.

Growing Industrial Applications

Beyond traditional construction, swivel couplers play an important role in industrial sectors. Refineries, power plants, and shipyards often require scaffolding in confined or irregular spaces where right-angle couplers fall short. Swivel couplers provide the necessary flexibility for:

-

Maintenance of large machinery and equipment.

-

Scaffolding on curved or irregular surfaces.

-

Access structures in restricted industrial environments.

-

Shipbuilding and dockyard applications.

As industries continue to expand and modernize, the use of swivel couplers is expected to rise.

European Safety Regulations

Europe has some of the strictest scaffolding regulations globally. Compliance with EN 74 standards ensures scaffolding couplers meet rigorous safety and performance benchmarks. As a result, companies prioritize purchasing from a trusted swivel coupler supplier in Europe, like Affix Scaffolding, to ensure compliance. This regulatory emphasis has boosted demand for quality-assured swivel couplers across all EU member states.

Key regulatory drivers include:

-

Mandatory safety compliance for scaffolding equipment.

-

Increased inspections on construction sites.

-

Stronger liability for contractors using substandard fittings.

Swivel couplers that meet these requirements offer peace of mind and long-term value to buyers.

Trends in Purchasing vs. Rentals

The European scaffolding market reflects a balance between purchasing and rental. While rental remains common for short-term projects, many contractors and companies prefer bulk purchases of swivel couplers because:

-

Purchased couplers offer long-term cost savings.

-

Bulk supply ensures equipment availability for multiple projects.

-

Contractors gain greater control over quality and compliance.

The trend toward bulk purchasing is particularly strong among mid-sized and large construction firms, fueling greater demand for swivel couplers for sale in Europe.

Market Factors Driving Growth

-

Urbanization: Growing cities require more residential and commercial scaffolding.

-

Renovation projects: Older European structures demand adaptable solutions.

-

Industrial growth: Expanding sectors such as energy, shipping, and manufacturing.

-

Safety compliance: Regulations pushing contractors toward standardized, certified products.

-

Technological advances: Stronger materials and improved galvanization increase product lifespan.

Technical Specifications

When choosing a swivel coupler for sale in Europe, technical specifications are a key consideration for construction professionals, contractors, and industrial buyers. These specifications determine the coupler’s strength, durability, and compatibility with scaffolding systems. For projects across Europe, compliance with safety and performance standards is non-negotiable, making it crucial to understand the details behind each swivel coupler.

Standard Sizes and Dimensions

Swivel couplers are designed to connect two scaffolding tubes at any angle. To ensure compatibility with commonly used scaffolding systems, they are produced in standard sizes:

-

48.3mm diameter – the most widely used tube size in European scaffolding.

-

Standard tube thickness – ensuring durability and structural integrity.

-

Custom sizes available – for specialized industrial projects requiring unique setups.

These standard dimensions allow swivel couplers to integrate seamlessly with scaffolding structures used across Europe.

Load Capacities and Performance

Load capacity is one of the most critical technical specifications when evaluating a swivel coupler in Europe. High-quality swivel couplers can withstand substantial pressure and distribute weight evenly across the scaffolding system.

Typical performance features include:

-

Safe working load: High resistance to bending and deformation.

-

Even load distribution: Ensures stability of the entire scaffold structure.

-

Resistance under dynamic loads: Suitable for projects involving movement, vibration, or heavy machinery.

-

Safety margins: Designed to exceed minimum safety requirements for added reliability.

Load-bearing performance ensures the coupler can endure demanding construction and industrial conditions.

Forged Steel Construction

Swivel couplers are typically manufactured from high-strength forged steel. This material provides:

-

Exceptional durability – withstands daily wear and tear.

-

High tensile strength – essential for supporting heavy loads.

-

Impact resistance – suitable for challenging construction environments.

-

Long service life – reducing the need for frequent replacement.

Forged steel swivel couplers are a preferred choice for contractors looking for reliability and safety in long-term use.

Galvanized Finish for Protection

To withstand European weather conditions and reduce maintenance, swivel couplers are often finished with galvanization. This process adds:

-

Corrosion resistance – prevents rusting in wet or humid climates.

-

Surface protection – increases durability against scratches and impacts.

-

Extended product lifespan – ensuring cost-effectiveness over multiple projects.

-

Minimal maintenance needs – reducing downtime and upkeep costs.

Galvanized swivel couplers perform well in outdoor construction and industrial projects across Europe.

Compliance with EN 74 Standards

In Europe, scaffolding components must meet the EN 74 standard, which governs safety, performance, and reliability. Choosing an EN 74-compliant swivel coupler supplier in Europe ensures:

-

Uniform quality across all fittings.

-

Assurance of safety in scaffolding systems.

-

Recognition across European markets.

-

Ease of inspection and approval by regulators.

Compliance with EN 74 gives contractors confidence that their equipment will pass strict safety audits.

Why Choose Affix Scaffolding for Swivel Couplers in Europe?

In Europe’s competitive construction industry, sourcing scaffolding components from a reliable supplier is vital for project success. When it comes to swivel couplers for sale in Europe, Affix Scaffolding stands out as a trusted provider delivering quality, compliance, and customer-focused service. Contractors, builders, and industrial clients across the continent rely on us as a leading swivel coupler supplier in Europe for durable and compliant scaffolding fittings.

Trusted Swivel Coupler Supplier Europe

Affix Scaffolding has positioned itself as a dependable supplier by offering high-quality swivel couplers that meet strict European standards. Buyers across different regions benefit from:

-

Consistency in quality – every coupler meets EN 74 requirements.

-

Reliable bulk supply – ensuring large-scale projects stay on schedule.

-

Market reputation – known for premium scaffolding solutions.

-

Professional support – guiding contractors in choosing suitable products.

This level of trust makes Affix Scaffolding the preferred partner for contractors and industrial buyers.

Wide Range of Products Tailored for European Projects

Construction projects differ in scale, design, and load requirements. Affix Scaffolding addresses these variations by offering an extensive selection of swivel couplers designed to handle diverse applications:

-

Standard swivel couplers – suitable for general construction projects.

-

Heavy-duty options – for industrial and infrastructure applications.

-

Galvanized finish couplers – providing long-lasting rust resistance.

-

Custom specifications – available upon request for specialized projects.

This variety ensures every buyer finds the right fit for their scaffolding system.

Competitive Pricing and Value

Affix Scaffolding is committed to making high-quality swivel couplers accessible without compromising affordability. Our pricing model focuses on:

-

Cost-effectiveness for bulk orders – ideal for contractors working on large projects.

-

Value for long-term use – forged steel and galvanization ensure durability.

-

No hidden costs – transparent quotes to help clients budget accurately.

-

Savings through durability – reducing replacement and maintenance costs.

Contractors benefit from dependable fittings while optimizing project budgets.

Europe-Wide Delivery Network

Timely supply is critical in construction. Affix Scaffolding supports its clients with efficient delivery services across Europe:

-

Fast turnaround times – minimizing delays in ongoing projects.

-

Wide coverage – delivering to multiple regions across Europe.

-

Flexible shipping options – tailored to order size and urgency.

-

Reliable logistics partners – ensuring safe transportation of products.

This distribution strength reinforces our role as a preferred swivel coupler supplier in Europe.

After-Sales Support and Service

Affix Scaffolding believes in long-term relationships with clients. Beyond supplying swivel couplers, we offer after-sales support to ensure satisfaction:

-

Responsive communication – addressing queries quickly.

-

Technical guidance – advising on load capacity, coating options, and compliance.

-

Replacement and warranty support – ensuring reliability after purchase.

-

Ongoing assistance – for future bulk orders and product selection.

This client-focused approach sets us apart in the European scaffolding market.

Buying Guide – Choosing the Right Swivel Coupler

Purchasing the right swivel coupler for sale in Europe is crucial for ensuring scaffolding safety, efficiency, and compliance. With multiple options available, contractors and industrial buyers must carefully assess specifications, materials, and standards before making a purchase. As a leading swivel coupler supplier in Europe, Affix Scaffolding provides guides to help buyers make informed decisions that suit their projects and budgets.

Key Factors to Consider

When selecting a swivel coupler in Europe, contractors should evaluate several factors that directly impact performance:

-

Tube Diameter Compatibility – ensure the coupler fits the scaffold tube size used in your system.

-

Load Capacity – choose a coupler that supports the structural weight requirements.

-

Material Quality – forged steel with galvanization enhances durability.

-

Compliance Standards – always select EN 74-certified couplers for European projects.

-

Coating & Finish – galvanized finishes provide resistance against rust and weather.

These considerations ensure that the couplers chosen deliver both safety and longevity.

Forged vs. Pressed Steel Swivel Couplers

Two major categories dominate the market: forged and pressed steel. Understanding their differences helps buyers decide:

-

Forged Steel Swivel Couplers

-

Superior strength and durability.

-

Suitable for heavy-duty and industrial applications.

-

Long lifespan with minimal wear under pressure.

-

-

Pressed Steel Swivel Couplers

-

Lightweight and more economical.

-

Suitable for lighter scaffolding structures.

-

Ideal for projects where weight savings are a priority.

-

For long-term reliability, most contractors prefer forged couplers, while pressed options remain attractive for cost-sensitive projects.

Choosing Based on Project Type

Different projects demand specific swivel coupler characteristics. Affix Scaffolding recommends:

-

Residential projects – pressed steel couplers for lighter scaffolding work.

-

Commercial construction – forged steel couplers for moderate to heavy loads.

-

Industrial and infrastructure projects – heavy-duty forged couplers with galvanization for durability.

-

Outdoor projects – always opt for galvanized finishes to withstand harsh weather.

By aligning coupler selection with project requirements, contractors maximize efficiency while ensuring safety.

Importance of Compliance with European Standards

Safety regulations in Europe are stringent, making EN 74 compliance non-negotiable. Buyers should confirm that their swivel coupler Europe purchase includes certification, ensuring:

-

Full compliance with EU safety requirements.

-

Enhanced worker protection on scaffolding systems.

-

Compatibility with other EN 74-certified scaffolding components.

-

Reduced liability for contractors and construction companies.

Affix Scaffolding ensures every coupler meets or exceeds these standards, giving buyers confidence in their investment.

How to Assess Quality Before Buying?

Contractors can verify the quality of swivel couplers by checking:

-

Surface finish – uniform galvanization with no sharp edges.

-

Welding and forging marks – strong joints without defects.

-

Weight and sturdiness – forged couplers should feel robust.

-

Locking mechanism – clamps should tighten securely without slipping.

-

Manufacturer details – genuine products carry identification for traceability.

These checks help buyers avoid substandard fittings that compromise safety.

FAQs

1. What is a swivel coupler used for in scaffolding?

A swivel coupler is designed to connect two scaffold tubes at any angle, offering flexibility for diagonal bracing or irregular structures. It ensures scaffolding remains stable and adaptable, especially for projects requiring non-standard frameworks, restoration work, or industrial scaffolding systems across Europe.

2. Are swivel couplers compliant with European safety standards?

Yes. High-quality swivel couplers supplied by Affix Scaffolding comply with EN 74 standards, ensuring durability, safety, and reliability. These certifications provide contractors with peace of mind that the products meet strict European regulations, making them suitable for large-scale construction, maintenance, and infrastructure projects.

3. What materials are swivel couplers made from?

Swivel couplers are commonly manufactured from forged or pressed steel and often finished with galvanization. This makes them both durable and resistant to corrosion, ensuring long-term performance in harsh environments. Contractors benefit from secure, high-strength fittings that support scaffolding structures across diverse European projects.

4. Can swivel couplers handle heavy loads?

Yes, swivel couplers are engineered to withstand significant loads while maintaining secure connections. Their robust construction allows them to support diagonal bracing and complex scaffold structures safely. Choosing EN 74-certified products ensures contractors across Europe can rely on them for demanding construction and industrial projects.

5. Are swivel couplers suitable for outdoor projects?

Absolutely. With galvanized finishes, swivel couplers resist rust and corrosion, making them ideal for outdoor projects exposed to changing weather conditions. Their versatility means they are widely used in construction, restoration, and industrial sites throughout Europe, ensuring long-lasting safety and stability in every application.

6. How do swivel couplers differ from double couplers?

A double coupler fixes scaffold tubes at right angles, while a swivel coupler connects tubes at any angle. This flexibility makes swivel couplers indispensable for diagonal bracing or complex designs. Contractors across Europe often use both coupler types together for secure and adaptable scaffold frameworks.

7. Do swivel couplers work with standard scaffold tubes?

Yes, swivel couplers are designed to be compatible with standard scaffold tubes used across Europe. This ensures seamless integration into existing scaffolding systems. Contractors benefit from quick assembly, reliable strength, and compliance with European standards, making them a versatile choice for various project needs.

8. What should I consider before buying swivel couplers?

Buyers should assess tube compatibility, load requirements, compliance with EN 74 standards, and whether the couplers are galvanized for durability. Working with a trusted swivel coupler supplier in Europe, like Affix Scaffolding, ensures the products meet safety regulations while providing long-term reliability and cost-effectiveness.

9. Can swivel couplers be purchased in bulk across Europe?

Yes, Affix Scaffolding supplies swivel couplers in bulk quantities to meet the needs of contractors, builders, and large projects across Europe. Bulk purchasing ensures cost savings, consistent product quality, and reliable delivery, helping companies streamline operations while securing premium scaffold fittings at competitive prices.

10. How can I order swivel couplers from Affix Scaffolding?

Ordering is simple. Contact Affix Scaffolding via 00 358 40 060 6046 or info@affixscaffolding.eu to request a free quote. Our team provides expert consultation, competitive pricing, and Europe-wide delivery, ensuring contractors receive high-quality swivel couplers in Europe products tailored to their project.